30

Jan

1. Selection of PCD Tool Grinding Machine

The mechanical cutting edge grinding of PCD tools mainly relies on the tribochemical reaction and surface fracture of diamond grinding wheel to remove the excess material. The particle size(grit), concentration and binder(bond) of diamond grinding wheel have a great influence on the quality and efficiency of PCD tool cutting edge grinding. Therefore, the correct selection of grinding wheel is very important. For the grinding wheel produced by MORESUPERHARD, the diamond grains are strictly screened and arranged in an orderly and uniform manner. The grinding removal rate per minute is 20 ~ 30 times that of the ordinary diamond grinding wheel. The experience shows that the grinding wheel with larger grain size should be selected as far as possible on the premise of satisfying the processing quality requirements. The recommended diamond grinding granularity is 22um for rough grinding. Semi-fine grinding grain 15um; Fine grinding particle size 9um. The polishing effect of our super fine grinding wheel 4000#-6000# is also particularly remarkable.

3. Balance of Diamond Grinding Wheel

After selecting the grinding wheel, the grinding wheel shall be balanced. Firstly, the grinding wheel balancer is placed on the mirror table for calibration. By adjusting the three balance nuts at the bottom of the balancer, the balance bubble in the balancer is placed in the center. Then, slide the grinding wheel into the adjusting rod of the grinding wheel, adjust the three balance screws on the side of the grinding wheel so that they are evenly distributed (clamping 63 Angle to each other is about 120), until the balance bubble in the balancing instrument is located in the center again, and the grinding wheel is balanced.

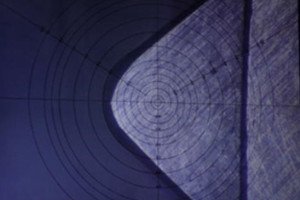

4. Clamping and adjust the PCD tool between the rotary center and the optical center

5. Selection of Wheel Swing

8. Treatment of PCD tools before and after edge grinding