30

Jan

Case Studies

Case I

| Workpiece | Gear |

| Cutting inserts | PCBN – SNGN201020 |

| Workpiece Materials | 40CrMo (45-55HRC) |

| Cutting Parameters | Roughing: Ap=4mm, f=0.7mm/r |

| Finishing: Ap=0.5mm, f=0.6mm/r | |

| Cutting Method | Gear Top cylindrical Turning |

|

|

Comparison

| Comparison | Cutting Speed | Efficiency | Life |

| Carbide inserts | 20m/min | 20h/pcs | 0.25pcs/edge |

| MORESUPERHARD

CBN inserts |

50m/min | 2h/pcs | 2pcs/edge |

Case II

| Workpiece | Bearing |

| Cutting inserts | PCBN—SNGN150720 |

| Workpiece Materials | Gr15 (55-62HRC) |

| Cutting Parameters | Vc=120m/min |

| Ap=4mm | |

| f=0.1mm/r | |

| Cutting Method | Cylindrical / Face turning |

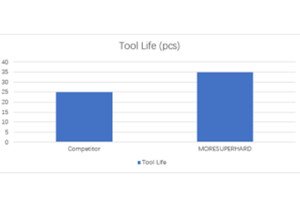

|

|

Case III

| Workpiece | Rotary Support Bearing |

| Cutting inserts | PCBN—RCGN090700 |

| Workpiece Materials | 42CrMo (47-55HRC) |

| Cutting Parameters | Vc=90m/min |

| Ap=0.2mm | |

| f=0.3mm/r | |

| Cutting Method | Inner Circle Turning |

|

|

Comparison

| Comparison | Cutting Speed | Efficiency | Life |

| Coated Alloy | 50m/min | 2h/pcs | 1pcs/edge |

| MORESUPERHARD

CBN inserts |

90m/min | 30min/pcs | 4pcs/edge |

Case IV

| Workpiece | Crankshaft |

| Cutting inserts | PCBN—DNGA110408 |

| Workpiece Materials | 42CrMo (42-47HRC) |

| Cutting Parameters | Vc=170m/min |

| Ap=0.3mm | |

| f=0.1mm/r | |

| Cutting Method | Excircle Interrupted Wet Turning |

|

|

Comparison