07

Aug

Types of stainless steel products

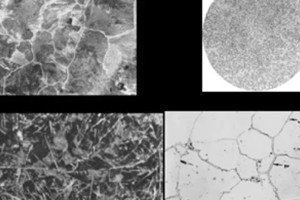

In the classification of metal materials, people often divide stainless steel into five categories according to their metallographic characteristics, namely: martensitic stainless steel, ferritic stainless steel, austenitic stainless steel, austenitic-ferritic duplex stainless steel, and precipitation hardening stainless steel. Among them, austenitic stainless steel is the most common, accounting for about 70% of the total stainless steel.

At present, stainless steel with Cr and Ni elements added at the same time accounts for more than 60% of the total stainless steel production. Compared with structural steel, stainless steel has poor thermal conductivity, low elastic modulus, high elongation, and large cross-sectional shrinkage, which brings many difficulties to processing, especially grinding.

Grinding characteristics of stainless steel

① Large grinding force and high grinding temperature

Stainless steel materials have the characteristics of high temperature, high strength and high toughness. During grinding, the lattice distortion is large and the plastic deformation is severe. The cutting force per unit area of stainless steel can reach 90GPa, and the grinding force is 1.5-2.2 times that of 45# steel. The grinding resistance is large and the temperature in the grinding area is high.

The thermal conductivity of stainless steel is low, about 1/3 of 45# steel, which causes the surface of the workpiece to instantly generate a high temperature of 1000-1500℃. The surface of the workpiece is easily burned and cracked. Sometimes the surface of the workpiece is annealed, and the annealing depth can reach 0.01-0.02mm.

②Severe work hardening trend

When stainless steel is ground, the surface of the workpiece is severely deformed, the stress and strain increase, and work hardening occurs. In the work hardening layer, the grains are distorted, the sand grains are worn and passivated, and vibration marks and scratches are produced.

③ Grinding chips adhere to the grinding wheel

Due to the great toughness of stainless steel, under certain grinding temperature, contact pressure and relative speed conditions, grinding chips can easily react with sand particles, so grinding chips adhere to the grinding wheel, fill the gaps between the abrasive particles, and cause the grinding wheel to clog rapidly. At this time, the grinding conditions deteriorate rapidly, the heat is serious, and the surface roughness decreases significantly.

The adhesion of grinding chips varies with different stainless steels. The grinding adhesion of concentrated nitric acid-resistant stainless steel and heat-resistant stainless steel is the most serious, followed by 1Cr18Ni9Ti, 1Cr13, 2Cr13, etc.

④ Grinding chips are not easy to cut off, and abrasive particles are easy to blunt

When grinding stainless steel materials, the grinding force is large, and the abrasive particles are easy to blunt, causing the grinding wheel to wear. Generally, when grinding stainless steel, the grinding ratio is G=6-12, while when grinding ordinary carbon steel and low-alloy steel, the grinding ratio is G=40-80. Therefore, the grinding ratio of stainless steel is only about 1/7 of that of ordinary steel.

⑤ Workpiece surface burn

Workpiece surface burn is one of the common defects in grinding, especially austenitic stainless steel, which is more sensitive to burn.

⑥ Workpiece surface scratch

When grinding stainless steel materials, the workpiece surface is easily scratched, so the roughness of the processed surface is required to be high.

⑦Workpiece deformation

Due to the large linear expansion coefficient of stainless steel, the grinding temperature has a great influence on the workpiece size, which can easily cause errors in size measurement. In addition, stainless steel has a serious tendency to work hardening, and residual stress is easily generated on the workpiece surface.

Especially when grinding slender shaft workpieces, thin-walled workpieces and other workpieces with poor rigidity, the workpiece is easily deformed under the action of grinding force.

Grinding solutions for stainless steel workpieces

1.How to choose grinding wheel abrasives?

CBN abrasives

Cubic boron nitride (CBN) grinding wheels are the best for grinding stainless steel. Due to the high hardness of CBN, the abrasive grains are not easy to wear, the chemical stability is good, and there is no chemical affinity with iron elements, so it is not easy to clog the CBN grinding wheel during grinding.

CBN grinding wheels have low grinding force, low grinding heat, and do not burn the workpiece. However, the price of CBN grinding wheels for stainless steel is higher than that of ordinary grinding wheels, and they need to be trimmed according to actual conditions.

Whrite corundum

When grinding stainless steel, white corundum (WA) grinding wheels are generally used. White corundum has good cutting performance and self-sharpening properties.

Single crystal corundum

The grinding effect of single crystal corundum grinding wheel is second only to CBN grinding wheel. Because each abrasive grain is a spherical polyhedral single crystal, there is no crack and residual stress caused by mechanical crushing. If the sudden crushing of a single abrasive grain is less, and the hardness and toughness match well, single crystal corundum has good grinding performance.

Microcrystalline corundum

When grinding Cr17Ni7A1 precipitation hardened stainless steel, use microcrystalline corundum (MA) grinding wheel. Microcrystalline corundum has high toughness, good cutting performance, long service life, self-sharpening cracking along the microcrystalline gap, will not cause large particles or the entire abrasive particles to fall off, which is conducive to reducing grinding heat and grinding wheel clogging.

Silicon carbide abrasives

When grinding austenitic stainless steel, using grinding wheels made of microcrystalline corundum and green silicon carbide can greatly reduce the roughness of the workpiece and reduce or eliminate burns.

How to choose abrasive size for grinding stainless steel?

Abrasive grain size has a direct impact on surface roughness. Stainless steel has high toughness and is easily clogged by grinding chips. If a fine-grained grinding wheel is used, the abrasive loses its cutting effect and the surface finish of the workpiece is not high. The results show that F36 and F46 grains are used for rough grinding, and F60 grains are used for fine grinding. F46 and F60 grain grinding wheels are used for both rough and fine grinding.

How to choose the bonding agent for grinding stainless steel grinding wheels?

Stainless steel has the characteristics of high toughness, high temperature resistance, high strength and large grinding force. Therefore, the grinding wheel is required to have high strength and be able to withstand large impact loads.

Vitrified Bond grinding wheels

When grinding stainless steel, a ceramic bond grinding wheel can be used. It has good waterproof, heat-resistant and corrosion-resistant properties, can maintain good cutting performance and has high production efficiency. The disadvantage is that it is very brittle and cannot withstand large impacts and bending.

Resin bond grinding wheels

Resin bond grinding wheels are used for cutting, grooving and centerless grinding of stainless steel. They have high strength, good elasticity, impact resistance, and many pores. They can be used at higher peripheral speeds (35-75m/s). However, the hardness of resin bond grinding wheels is relatively low. Putting resin bond grinding wheels in paraffin can prevent the influence of alkaline solutions. In addition, when the temperature is higher than 150°C, the resin bond will soften, reduce strength, and even burn, so it should be cooled during grinding.

When grinding stainless steel, CBN grinding wheels and ordinary grinding wheels should be selected according to the economic situation and the actual situation of the grinding material. In addition, ordinary abrasive belts and CBN abrasive belts are also used for grinding in actual applications.

Moresuperhard has always been committed to the research and development and production of more advanced diamond and CBN grinding wheels to provide customers with complete grinding solutions!