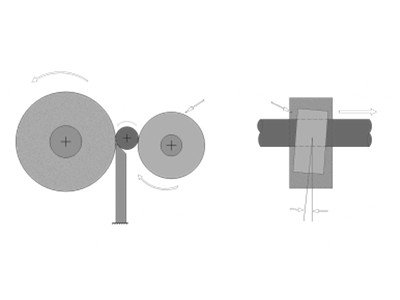

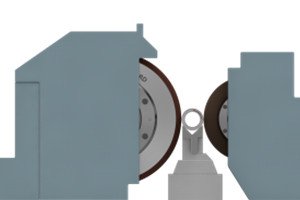

Centerless grinding is a high-productivity precision machining method that uses the surface of the workpiece to be machined as the positioning surface.

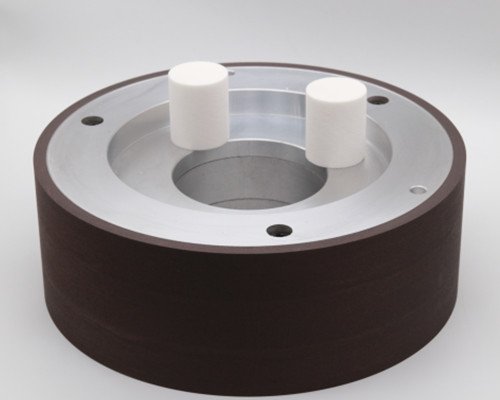

Characterstics of centerless grinding wheel

High precision: Since centerless grinding does not require a center hole, there will be no impact of the center hole deviation on the workpiece accuracy, making the ground workpiece have higher accuracy.

Good surface quality: During the centerless grinding process, there are fewer grinding marks on the workpiece surface, and better surface quality can be obtained.

High production efficiency: Centerless grinding can grind multiple workpieces at the same time, greatly improving production efficiency.

Energy saving: Since centerless grinding does not require a center hole, many unnecessary operating steps can be reduced, thereby saving energy.

Specifications of centerless grinding wheel

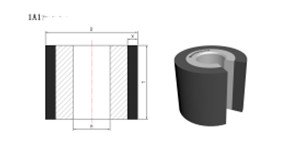

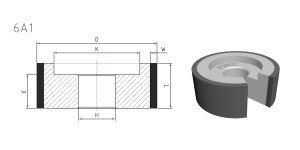

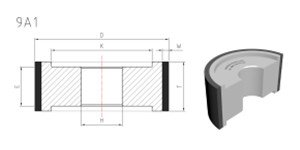

| Model | Drawing | Universial Spec | |

| 1A1 |  |

D | 125-600 |

| H | 75,125,203 | ||

| X | 5,10 | ||

| 6A1 |  |

D | 125-600 |

| H | 75,125,203 | ||

| X | 5,10 | ||

| 9A1 |  |

D | 125-600 |

| H | 75,125,203 | ||

| X | 5,10 | ||

| Other sepcifications all can be customized | |||

Why Choose Moresuperhard centerless grinding wheel

1. Good concentricity and precision. All are implemented in accordance with industry standards, and the quality is basically equivalent to German quality.

2. The size tolerance of the centerless grinding wheel is controlled at +/- 0.2mm to ensure dimensional accuracy.

3. With professional production equipment and technology, we can produce centerless grinding wheels of various sizes and achieve high quality;

4. Our factory’s centerless grinding wheels have been exported to Southeast Asia, America, and Europe for many years. We understand the requirements and specific uses of products in different regions, so we can more effectively produce efficient and durable products.