05

Sep

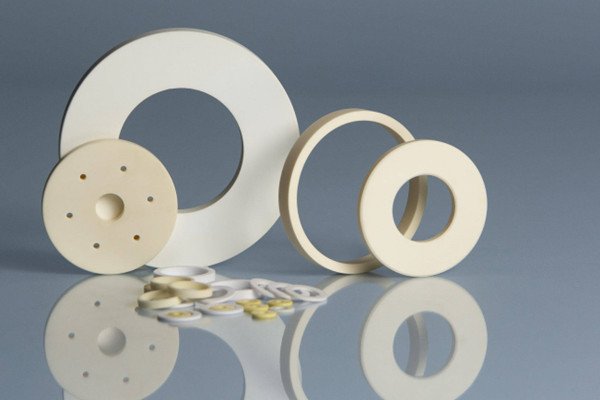

Alumina ceramics are a type of ceramic material with aluminum oxide (Al2O3) as the main component. They have excellent physical, chemical and mechanical properties and are widely used in various fields, such as electronics, machinery, and chemical engineering. This material is widely used in various scenarios due to its unique properties, including but not limited to thick film integrated circuits, electronic ceramic parts, wear-resistant ceramic linings, refractory and high-temperature resistant materials, etc.

Excellent physical, chemical and mechanical properties: Alumina ceramics have high hardness, high wear resistance, high corrosion resistance, high mechanical strength, good electrical insulation properties and low dielectric loss, which make it perform well in various harsh environments.

High purity and ordinary type: According to the content of Al2O3, alumina ceramics are divided into high purity and ordinary types. High purity alumina ceramics have an Al2O3 content of more than 99.9%, and are mainly used to make high-temperature crucibles, refractory furnace tubes and special wear-resistant materials; ordinary alumina ceramics are divided into 99 porcelain, 95 porcelain, 90 porcelain, 85 porcelain, etc. according to the content of Al2O3, and are used to make corrosion-resistant and wear-resistant parts.

At present, the difficulty of machining alumina ceramic substrates is mainly reflected in machining hardness and machining brittleness.

The crystalline form of α-Al2O3 is mostly covalent bonds or ionic bonds formed by aluminum ions and oxygen ions, so the binding energy between atoms is very high and has strong directionality, which is specifically manifested as small plastic deformation, large material brittleness, and easy cracking.

On the other hand, in general, the microstructure of alumina ceramics is equiaxed grains, which are polycrystalline structures composed of covalent bonds or ionic bonds. Therefore, the fracture toughness is low. Under the action of external loads, stress will cause fine cracks on the ceramic surface, and the cracks will expand rapidly and then brittle fracture will occur.

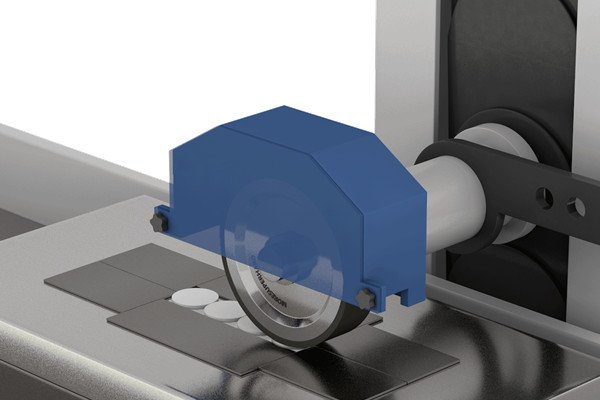

Alumina ceramic materials have high hardness, so grinding wheels usually use diamond materials as abrasives.

During the grinding process, the material removal methods mainly include grain removal, brittle fracture, material stripping, grain boundary micro-crushing, etc. The gaps and cracks on the ceramic surface go through four stages of forming, extension, stripping, and rupture, so that the entire grain falls off the workpiece surface, completing the brittle material removal process.

Diamond grinding wheels are the most common choice due to the high hardness of ceramic aluminum oxide. Diamond is harder than aluminum oxide and can grind it effectively.

Grinding wheel grit: Choose a fine-grit grinding wheel, usually between 325 and 600 mesh, to achieve a good surface finish.

Binder: Metal binders and resin binders are commonly used for grinding ceramic alumina. Metal binders are durable, while resin binders can reduce heat buildup during grinding.

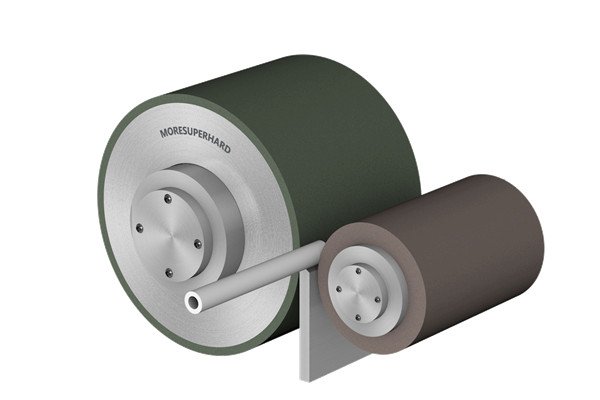

Moresuperhard provide quality diamond grinding wheel for alumina ceramic workpieces.Resin bond diamond wheel,metal diamond wheel,ceramic bond diamond wheel all can we provide.Moresuperhard have many successful alumina ceramic grinding case for your reference.Welcome you inquire.