09

Oct

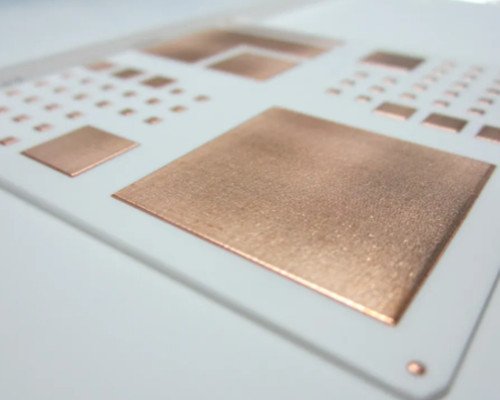

Ceramic substrate is a sheet material based on electronic ceramics that forms a supporting base for circuit components. It is the most popular packaging material for the new generation of communication and new energy automotive electronic devices, and is the preferred material for achieving high-density integrated heat dissipation.As a substrate material with excellent performance, ceramic substrates are widely used in electronic packaging, power devices, high-temperature electronic devices and other fields.

Strong mechanical stress: stable shape, high strength and high thermal conductivity.

Strong bonding: anti-corrosion, excellent thermal cycle performance, high reliability.

No pollution, no pollution: various graphics can be etched.

Wide operating temperature: The thermal expansion coefficient is close to that of silicon, which is similar to that of components.

At present, the materials of ceramic substrates are mainly divided into alumina, aluminum nitride, silicon nitride, silicon carbide, etc.

Alumina is the most commonly used substrate material due to its high strength, good thermal conductivity and electrical insulation properties. It also stands out for its chemical stability and richness. Alumina ceramic substrates are inexpensive and have the widest range of applications.

However, the thermal conductivity of alumina ceramic substrates is relatively weak, and they are subject to certain restrictions in some application scenarios with extremely high heat dissipation requirements.

Aluminum nitride has a high thermal conductivity, which is several times that of alumina ceramic substrates. This makes it excellent in heat dissipation of high-power electronic devices, and can effectively conduct heat away quickly to ensure the stable operation of electronic devices. Its good insulation performance can provide reliable electrical isolation and prevent short circuits and leakage between circuits.

Aluminum nitride ceramic substrates also have a thermal expansion coefficient close to that of silicon, which helps to reduce stress caused by thermal expansion differences when the temperature changes, and improve the reliability and service life of the package.

The relatively high production cost of aluminum nitride ceramic substrates limits their large-scale use in some cost-sensitive applications.

At present, aluminum nitride ceramic substrates are mainly used in high-power LED lighting, IGBT modules, optical communications and lasers, aerospace and military fields.

Application comparison Alumina ceramic substrates have advantages in cost and mechanical strength, and are often used in electronic devices that are not very demanding on heat dissipation and cost-sensitive, such as ordinary consumer electronics, lighting equipment, etc.

Aluminum nitride ceramic substrates perform better in thermal conductivity and thermal matching, and are often used in high-power electronic devices, high-frequency communication equipment, LED lighting and other fields that have high requirements for heat dissipation and high-frequency performance.

Silicon nitride has excellent mechanical properties, high strength, high hardness, and can withstand large mechanical stress. At the same time, it has a low thermal expansion coefficient and high thermal conductivity, which makes it stable in an environment with temperature changes and has good thermal shock resistance. In terms of electrical properties, silicon nitride has good insulation and dielectric properties.

However, silicon nitride ceramic substrates face the challenges of high production costs and difficult processing.

At present, silicon nitride ceramic substrates are mainly used in rail transportation, smart grids, aerospace and other fields.

![]()

Silicon carbide ceramic substrate has the characteristics of high thermal conductivity, high strength, high temperature resistance, chemical corrosion resistance, etc. In the power module of new energy vehicles, the use of silicon carbide ceramic substrate can improve the heat dissipation efficiency of the module, thereby improving the vehicle’s cruising range and performance; in the aerospace field, its high temperature resistance and high reliability can meet the needs of electronic equipment in extreme environments.

Application comparison Compared with silicon nitride ceramic substrates, silicon carbide ceramic substrates have advantages in thermal conductivity and are suitable for high-power and high-temperature heat dissipation scenarios.

![]()

Silicon nitride ceramic substrates have characteristics in mechanical strength and certain electrical properties, and are suitable for special environments with high reliability requirements.

The production costs of both are relatively high, but due to the relatively complex preparation process of silicon carbide ceramic substrates, their costs are usually higher than those of silicon nitride ceramic substrates.

Integral diamond blades are commonly used for cutting ceramic substrates. Resin diamond hubless dicing blades, metal bond diamond dicing blades, and electroplated diamond dicing blades can all be used. The specific blade type should be differentiated according to the material conditions, and the impact of the surface metal on the cutting quality should be considered. For specific cutting plans, please consult the MORESUPERHARD soft blade application team.