06

Nov

Graphite is a material with excellent electrical conductivity, thermal conductivity and high temperature resistance, as well as good lubricity and chemical stability. Due to its layered structure, graphite can maintain good performance under high temperature and high pressure. These properties make graphite widely used in batteries, lubricants, refractory materials, electronic components, and aerospace and automotive industries. In addition, graphite is also used to make synthetic diamonds and other high-performance materials.

During the grinding process, graphite parts are soft and will be affected by factors such as the grinding wheel particle size and grinding method, causing various defects on the surface of the parts:

① Polygonal defects. There are equidistant straight line marks along the axis of the part surface.

② Spiral defects. The grinding surface shows a spiral mark.

③ Scratches or scratches. Obvious engraved grinding marks appear on the surface, some large, some small, some long, some short.

When selecting a wheel for graphite, consider the grit size (coarse for rough grinding and fine for finishing) and the specific application requirements. Always ensure that the wheel is designed for use with graphite to achieve optimal results.

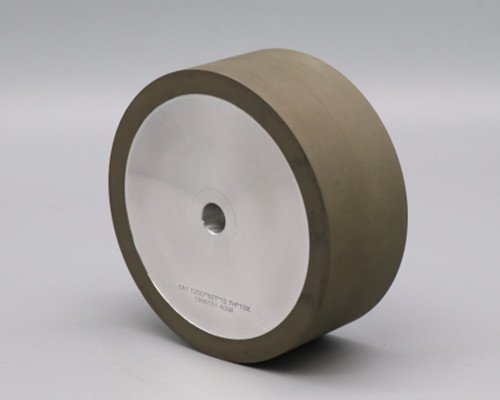

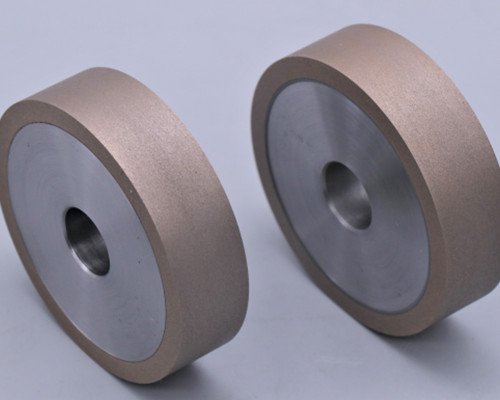

Resin bond diamond grinding wheel

Resin bond graphite grinding wheel is suitable for rough grinding and polishing, with high strength and durability. This grinding wheel is suitable for various graphite processing needs, with relatively low price, suitable for large-scale production

Electroplated diamond grinding wheel

Electroplated diamond grinding wheel is suitable for high-precision processing and can provide better mirror effect. This grinding wheel is suitable for precision processing and can meet the requirements of high precision and high finish

Metal Bond Diamond Wheels

Metal bond diamond grinding wheels are more rigid and can be used for rough grinding. They provide longer tool life but may generate more heat, so effective cooling is essential.

Generally, the graphite workpiece is processed by a combination of rough and fine grinding. During rough grinding, the grinding allowance of the parts is large, and the grinding method of positioning lateral feed is adopted. Since the grinding wheel and the graphite parts have a large contact surface during rough grinding, it is easy to heat up during grinding, so the cooling should be sufficient during rough grinding. During fine grinding, longitudinal feeding is adopted, and lateral feeding is performed during the grinding process. The grinding wheel has a small cutting amount, which can effectively ensure the processing accuracy and size requirements of the parts.