26

Dec

In modern manufacturing, the continuous advancement of precision machining technology has put forward higher requirements for machining quality and efficiency. As an efficient and wear-resistant grinding tool, electroplated diamond grinding heads are widely used in the precision machining of CNC (computer numerical control) equipment due to their excellent hardness, wear resistance and high temperature stability.

The production line of a certain automotive parts manufacturing customer needs to process a batch of complex high-hardness steel parts, requiring the processing surface to be smooth and high-precision, and the heat-affected zone during the processing must be controlled very small.

The main material of these parts is H13 tool steel, with a hardness of 50-55HRC, and the surface processing requirement is to be below Ra0.4. The contour shape of the parts is complex and needs to be precisely ground by CNC equipment.

In the processing of traditional carbide grinding wheels and other grinding tools, there are often problems such as high grinding temperature and substandard surface quality. In order to solve these problems, Moresuperhard recommended customers to use electroplated diamond grinding heads to process these parts.

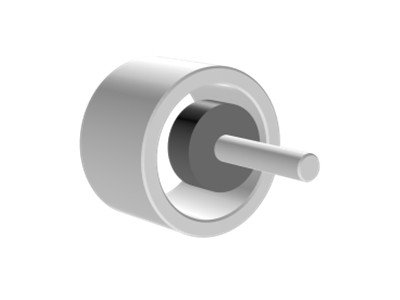

Electroplated diamond grinding heads are made by coating diamond particles on the grinding head substrate to form an extremely hard and wear-resistant grinding tool. Compared with traditional ceramic grinding wheels or resin bonded grinding wheels, electroplated diamond grinding heads have the following advantages:

Higher cutting efficiency

Electroplated diamond grinding heads have higher cutting efficiency and can maintain stable processing performance during high-speed grinding.

No dressing is required for the following reasons

· Single-layer structure design

Electroplated grinding wheels form a working layer by firmly coating diamond particles on the surface of the substrate, and the thickness is usually only a single layer. Since there is no multi-layer abrasive structure, new abrasive particles cannot be exposed through dressing after wear.

· High stability of shape and size

Electroplated grinding wheels have been processed according to precise shapes and sizes during manufacturing, and do not need to be restored to shape through dressing during use.

By using the electroplated diamond grinding head produced by Moresuperhard, the surface quality of the parts is significantly improved during the processing of H13 tool steel parts on CNC equipment, the surface roughness reaches below Ra0.4, the dimensional accuracy is stable, and it meets the strict requirements of customers. Compared with traditional grinding wheels, electroplated diamond grinding heads have longer service life and higher processing efficiency, effectively reducing production costs.