25

Mar

In modern manufacturing, precision machining technologies continue to evolve to meet the growing demands for high accuracy and efficiency. Among these, rotary table electromagnetic grinding has gained significant attention for its ability to enhance machining quality in industries such as automotive, electronics, and mold manufacturing.

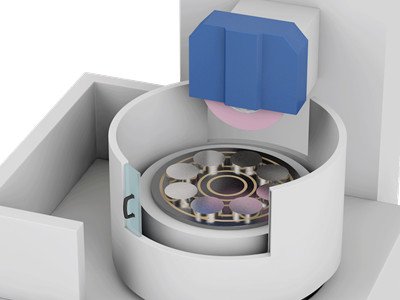

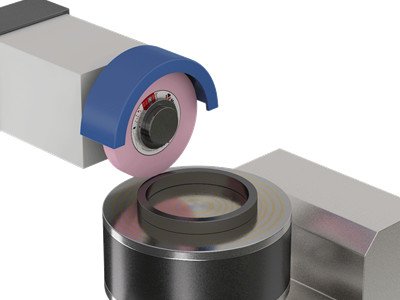

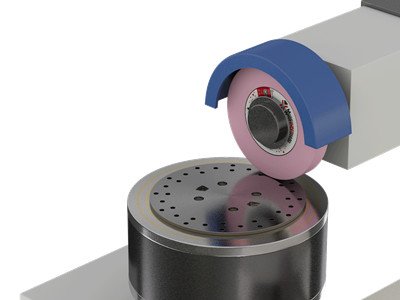

Rotary table electromagnetic grinding is a machining process that combines electromagnetic workpiece fixation with high-speed grinding. The method utilizes an electromagnetic chuck to securely hold the workpiece, while a rotating table and high-speed grinding wheel achieve efficient end-face machining. This technology is particularly suitable for thin-walled parts, easily deformable materials, and components requiring high flatness, eliminating deformation and stress concentration issues caused by traditional clamping methods.

High Stability: The electromagnetic chuck ensures the workpiece remains firmly fixed during grinding, reducing vibration and improving machining accuracy, especially for thin-walled parts.

High Efficiency: Compared to conventional clamping methods, electromagnetic fixation reduces setup time, making it ideal for mass production and improving overall productivity.

Wide Material Compatibility: In addition to ferromagnetic materials like steel and cast iron, certain non-magnetic materials (e.g., ceramics and aluminum alloys) can also be processed using auxiliary fixtures.

Superior Surface Quality: The combination of high-speed grinding and stable workpiece fixation enables micron-level precision, enhancing flatness and surface smoothness.

1. Automotive Manufacturing

Rotary table electromagnetic grinding is widely used for machining components such as brake discs and clutch plates. These parts require exceptionally high flatness and dimensional accuracy to ensure vehicle safety and longevity.

2. Electronics Industry

In the precision processing of ceramic substrates and semiconductor components, this technology provides high-quality surface grinding, improving the stability and reliability of electronic products.

3. Mold Manufacturing

The process is also applicable to the machining of precision mold components, such as high-accuracy guide rails and mold accessories, ensuring the longevity and precision of molds.

Selecting the appropriate grinding wheel is crucial to achieving optimal results for different materials and machining requirements:

Diamond Grinding Wheels: Best suited for ceramics, carbide, and other high-hardness materials.

CBN Grinding Wheels: Ideal for hardened steel, high-speed steel, and other hard metals.

Aluminum Oxide or Silicon Carbide Grinding Wheels: Suitable for common metals such as stainless steel and regular steel.

With its high efficiency, precision, and stability, rotary table electromagnetic grinding has become an essential machining technique in modern manufacturing. Whether for mass production in the automotive sector or ultra-precision processing in electronics, this technology delivers outstanding performance. As the demand for high-precision machining continues to grow, rotary table electromagnetic grinding is set to play an increasingly vital role across multiple industries.

If you have any inquiries regarding rotary table electromagnetic grinding or grinding wheel selection, feel free to contact us for expert guidance and tailored solutions!