Carbon fiber composites have high strength and rigidity, and significant lightweight effects, so they are widely used in aerospace and automotive fields.

Processing difficulties: Fiber pullout or matrix fiber detachment: During the processing process, carbon fiber is easily pulled out or detached from the matrix, resulting in poor surface quality of the workpiece and affecting the performance. Influence of cutting force and cutting temperature: The high heat resistance and wear resistance of the material make the cutting force and cutting temperature high during the processing, which can easily cause equipment wear and workpiece surface damage.

Processing defects: Burrs, delamination, edge collapse and other phenomena are prone to occur during the processing, affecting the strength and life of the workpiece

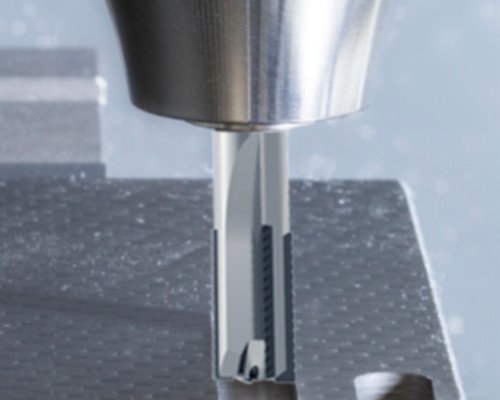

It can replace the traditional diamond grinding head grinding and diamond coated tool cutting, truly achieving the effect of integrated milling and grinding, and realizing high-efficiency and high-quality processing solutions for many customers.

The specifications can be customized according to the needs, high precision requirements, accuracy ≤ 0.01mm, the overall PCD micro-diameter milling cutter diameter can be 0.5mm, the overall PCD micro-diameter drill can be 0.3mm

High wear resistance – PCD material is more wear-resistant than traditional cemented carbide and is suitable for long-term high-precision machining.

Low loss – Long tool life, reduced replacement frequency, and reduced machining costs.

Optimized tooth shape design – Staggered tooth structure and dense tooth design, suitable for shallow milling and side milling of carbon fiber materials, with no burrs, no broken edges, and no flanging on the machined surface.

High-precision machining – Small cutting force of the tool, reducing heat accumulation and damage to the workpiece.

Carbon fiber composite material (CFRP)

Glass fiber composite material (GFRP)

Other high-performance composite materials

Case 1: Aerospace Industry – Carbon Fiber Composite Structural Parts Machining

Customer Background: A leading aerospace manufacturer specializing in aircraft structural components made from carbon fiber composites.

Problem: The customer previously used carbide end mills for CFRP machining, resulting in severe burrs, chipping, and short tool life, leading to low processing efficiency.

Solution: Recommended using Moao PCD micro-edge end mills for side milling and shallow plunge milling, along with optimized cutting parameters.

Result: The machining process significantly reduced burrs and chipping, improved efficiency by 30%, and increased tool life by four times.

Case 2: Automotive Industry – Precision Machining of Carbon Fiber Components

Customer Background: A high-end automotive manufacturer utilizing carbon fiber materials for lightweight vehicle body parts.

Problem: Traditional cutting tools caused delamination and fiber pull-out, compromising part quality.

Solution: Moresuperhard PCD micro-edge end mills were used for precision machining, with optimized feed rates and controlled cutting forces.

Result: The surface finish improved significantly, the part qualification rate increased to 98%, and overall production costs were reduced by 25%.

Case3:Electronic and Optical Industry-Milling Machining Quartzs Glass

Customer Background:A high-end manufacturer specializing in precision machining of quartz glass used in advanced electronic and optical applications.

Problem:The customer was facing challenges with their traditional cutting tools, particularly when machining quartz glass. The existing tools caused issues like poor cooling, debris accumulation, and inconsistent surface finishes, compromising part quality and precision.

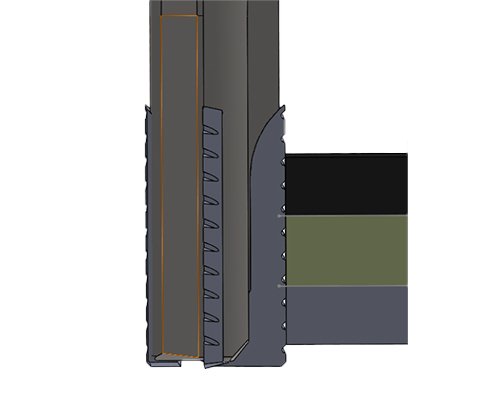

Solution:To address these challenges, the customer opted for Moresuperhard PCD Micro-Edge Milling Cutters. The tool used was D3.5-R0.3-0.6H-D3.4-10H-31F-6D-40I, featuring 31 blades and a central outlet for internal cooling. The customer required water to flow from the center of the tool for optimal cooling during the milling process. However, since the tool head is made of solid PCD, drilling holes in the PCD layer to allow water flow was required, which many competitors were unable to achieve.

More Super Hard successfully drilled holes in the PCD layer, allowing the tool to effectively discharge water from the center, providing enhanced cooling and debris removal during the milling process.