03

Apr

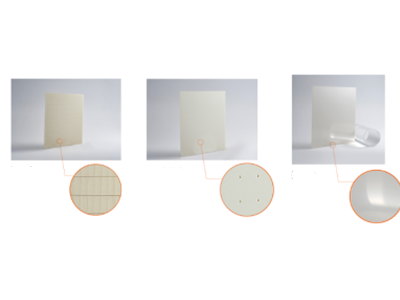

Common ceramic materials such as alumina ceramics, silicon carbide ceramics, silicon nitride ceramics and titanium carbide ceramics have a hardness of up to HV2250-3000, which is higher than cemented carbide and second only to diamond and cubic boron nitride. In addition, ceramic materials are very easy to crack. If improper tools or processing parameters are used during cutting, the cutting surface may be rough, cracks may expand, and even the workpiece may be scrapped. Therefore, traditional mechanical processing methods are difficult to meet the requirements of high-precision and high-quality ceramic cutting.

To solve this problem, the ultra-thin diamond cutting blade developed by Moresuperhard has shown excellent performance in ceramic cutting, greatly improving processing efficiency and cutting quality.

1A8 Solid Diamond Cutting Blades

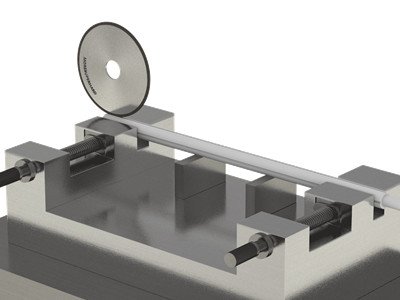

The integral ultra-thin diamond cutting blade is made of the same material. It is thin and high-precision, and is mostly used for high-precision, small-cutting-depth ceramic grooving and cutting.

The specific dimensions and precision are as follows:

| D | 25-60 | 70-78 | 80-110 | 110-125 | 127-200 | Thickness limit deviation(e) |

| T | ||||||

| 0.07 | ±0.002 | |||||

| 0.1 | ||||||

| 0.2 | ||||||

| 0.3 | ±0.003 | |||||

| 0.4 | ||||||

| 0.5 | ||||||

| 1.0 | ||||||

| 1.5 | ||||||

| 2.0 | ||||||

| H | 6,8,10,12.7,16,25.4,31.75,40,41.725,50.8,69.875,76.2,88.9,114.3 | |||||

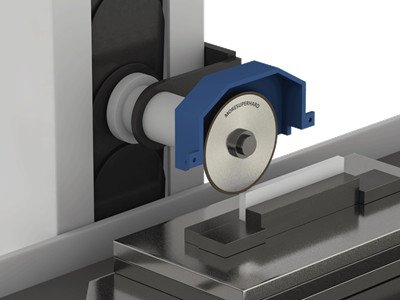

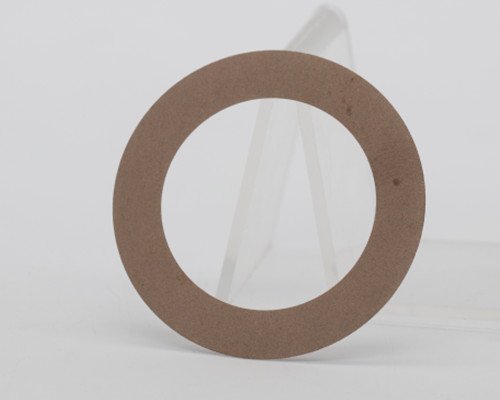

1A1R Hub Diamond cutting discs

1A1R cutting disc refers to a steel body and abrasive working layer,also known as an outer diamond layer cutting blade, it is slightly thicker,good rigidity, and is mostly used for grooving and cutting with medium and large cutting depths.

| D | 50-100 | 101.6-127 | 130-160 | 175-203 | 250-400 | Thickness limit deviation(e) |

| T | ||||||

| 0.2 |

1A1: ±0.005

1A1R: ±0.010 |

|||||

| 0.3 | ||||||

| 0.4 | ||||||

| 0.5 | ||||||

| 0.6 | ||||||

| 0.7 | ||||||

| 0.8 | ||||||

| 0.9 | ||||||

| 1.0 | ||||||

| 1.5 | ||||||

| 2.0 | ||||||

| H | 12.7,19.05,20,22.225,25.4,31.75,32,40,50.8,52,60,69.875,88.9,127,191.23 | |||||

Electronic ceramics: such as semiconductor packaging substrates, MLCC capacitor ceramic materials.

Medical devices: such as precision cutting of zirconia dentures and ceramic bone implants.

Precision optics: used to cut high-hardness optical ceramic lenses.

New energy materials: such as lithium battery diaphragm ceramic coating materials.

A customer mainly produces high-end zirconia ceramic tools. Its cutting requirements require a cutting width of less than 0.2mm, which is difficult to meet with ordinary grinding wheels. After testing, Moao’s integral ultra-thin diamond cutting blade successfully achieved high-precision cutting, with a cutting width of only 0.18mm, no cracking on the edge of the tool, and a service life of 30% longer than that of traditional cutting blades.

Ceramic cutting requires extremely high tool performance, and traditional processing methods are not up to the task. Moresuperhard diamond ultra-thin cutting blades provide superior solutions for ceramic cutting with their high precision, high rigidity and low loss. Whether it is small cutting depth and high precision processing, or large cutting depth and high rigidity processing, Moao can provide suitable cutting blade products to meet the different needs of customers.