18

Apr

In the process of internal hole grinding, customers not only pursue the processing life of grinding tools, but also have higher and higher requirements for the dimensional accuracy, shape accuracy and surface quality of workpieces. Common internal hole grinding tools include internal grinding wheels, honing heads, grinding rods, etc.

In the field of precision machining, honing and internal grinding are two commonly used processes. They are good at different processing scenarios, and understanding their differences can help us better choose the appropriate processing method.

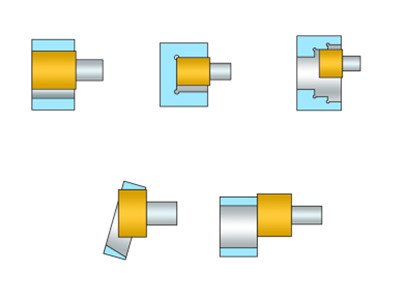

Internal grinding uses abrasive particles coated or pressed on the grinding tool. Under a certain pressure, the grinding tool and the workpiece move relative to each other to perform finishing on the machined surface. The inner hole to be ground may be a simple cylindrical surface or a surface with complex and precise contour requirements. Wide range of applications: can process various shapes such as inner circle, outer circle, plane and cone.

High processing accuracy: reaching IT5-1, the surface roughness can be controlled at Ra0.63-0.01μm.

It is commonly used for processing workpieces of metal and non-metal materials, such as bearing steel, high-speed steel, titanium alloy, PVC material, high-temperature alloy, tungsten steel, zirconium oxide/aluminum oxide ceramics, silicon carbide, quartz glass, composite materials, etc., but high-speed grinding may cause thermal damage.

• Mechanical manufacturing field: used to process the inner holes of various mechanical parts, such as the inner holes of bearings, transmission shafts, hydraulic cylinders, etc., to ensure the accuracy and matching performance of the parts.

• Mold manufacturing industry: Precision processing of the inner holes of molds to improve the molding accuracy and surface quality of molds, thereby ensuring the service life and production efficiency of molds.

• Air-conditioning compressor industry:

Internal grinding heads are widely used in the manufacture of air-conditioning compressors, especially in the inner hole processing of pistons, cylinders, and cylinder heads.

• Automotive parts industry: In the inner holes of automotive parts such as universal joints, star sleeves, bell housings, automobile engine cylinder blocks, transmission housings, etc., internal grinding heads are used to ensure their dimensional accuracy and surface finish to meet the requirements of high performance and high reliability of automobiles.

• Aerospace field: Processing the inner holes of aircraft engine blades, wing structural parts, etc. These parts have extremely high requirements for accuracy and strength. Internal hole grinding can meet their strict quality standards, thereby ensuring the performance and safety of mechanical parts.

• Medical equipment manufacturing: used to process the inner holes of key components in medical diagnostic equipment and accessories, such as syringe barrels, precision pipe fittings of medical equipment, etc., to ensure their precision and surface quality, and to ensure the accuracy and reliability of medical equipment.

• Precision engineering: In the processing of workpieces that require high precision and meticulous surface treatment, the internal grinding head can efficiently remove materials and form a high-precision inner hole surface.

The diameter of the internal grinding wheel should not be too large or too small. When grinding the inner hole, if the diameter of the grinding wheel is too large, the contact arc between the grinding wheel and the workpiece will increase, which will increase the grinding heat and make cooling and chip removal difficult. If the diameter of the grinding wheel is too small, it is difficult to achieve the ideal grinding speed (30m/s~50m/s), which will increase the grinding thickness, increase the load on the abrasive particles, and easily blunt the surface, increase the roughness of the inner hole, and reduce production efficiency. In order to obtain a good grinding effect, the grinding wheel diameter and the inner hole diameter should maintain an appropriate ratio, which is usually between 0.5 and 0.9. When the aperture is small, the main problem is the low peripheral speed of the grinding wheel, and a large ratio should be taken at this time; when the hole spacing is small, the main problem is the difficulty of cooling and chip removal, and a smaller ratio should be taken at this time. The selection of the internal grinding wheel diameter can refer to the following table.

| Diameter of processed hole/mm | Grinding wheel diameter/mm | Diameter of processed hole/mm | Grinding wheel diameter/mm |

| 15 | 10 | 45 | 38 |

| 20 | 15 | 55 | 48 |

| 25 | 20 | 65 | 58 |

| 30 | 25 | 75 | 68 |

When grinding the inner circle, the thickness of the grinding wheel should not be too thick or too narrow. If the grinding wheel is too narrow, the grinding wheel is easy to wear, which is not conducive to improving production efficiency and reducing surface roughness. If the grinding wheel is too thick, the grinding force will increase, which will easily cause the grinding wheel to bend and deform. Therefore, when grinding the inner hole, the appropriate grinding wheel thickness should be selected. Within the range allowed by the rigidity of the long shaft and the power of the machine tool, the grinding wheel thickness can be selected according to the length of the workpiece, see the table below.

| Grinding length/mm | Grinding Wheel Thickness/mm |

| 14 | 10 |

| 30 | 25 |

| 45 | 32 |

| 50 | 40 |

With the continuous advancement of science and technology, internal hole grinding technology is also constantly developing and innovating. For example, abrasive flow polishing technology, as an emerging internal hole processing method, can achieve high finish and high precision processing of the internal hole surface, while improving the hardness and mechanical properties of the material. In addition, precision CNC honing technology is also developing, its processing accuracy and efficiency are constantly improving, and its application range is becoming more and more extensive.

Honing is mainly used for processing internal holes, suitable for a ratio of hole depth to hole diameter of more than 10. Under certain grinding conditions, milling is used to process planes, outer cylindrical surfaces, spherical surfaces and tooth surfaces.

Better surface quality: After honing, the surface of the workpiece is cross-netted, which is conducive to lubricating oil storage and improves wear resistance.

Low-speed processing, small temperature rise: large contact area with the workpiece, small heat generated, and avoid thermal damage.

Almost no sand embedded: the processing process is gentle and will not damage the workpiece surface.

✳Processing object

Internal grinding is suitable for a variety of shapes, especially high-precision workpieces.

Honing focuses on high-quality internal hole processing, while taking into account other simple shapes.

✳Heat damage and sand problems

Internal grinding may cause surface damage and sand embedding due to high-speed processing.

Honing effectively avoids these problems through low-speed and gentle processing.

✳How to choose?

If you need to process complex shapes or high-porosity materials, it is more appropriate to choose internal grinding.

If you pay more attention to surface quality and workpiece durability, honing is a better choice.

Honing and internal grinding each have their own unique advantages. Choosing the right process is the key to achieving high-quality processing results. Whether it is precise dimensional control or excellent surface treatment, these two processes are indispensable tools in the field of internal hole precision grinding!

MORESUPERHARD has always been committed to the research and development and production of difficult-to-machine materials. From the selection of raw materials to the production of grinding wheels, we have strict quality inspection and control in every link. We pay attention to every detail and provide customers with superhard tools that are stable in quality, wear-resistant and meet customers’ processing needs. According to the material of the product that the customer grinds, MORESUPERHARD provides customized diamond/CBN tools with different formulas and different particle sizes, precise services, helping customers solve grinding problems, helping customers reduce costs and increase efficiency, and achieve revenue growth.