22

Apr

A precision ceramics manufacturer reported issues using a resin bond diamond double-disc grinding wheel for silicon carbide ceramic wafers. Main problems included surface burning, reduced tool life, and frequent dressing.

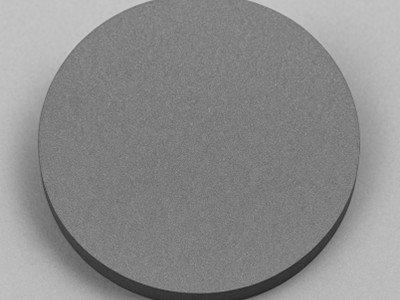

Material: Silicon Carbide (SiC) Ceramic

Workpiece Size: Ø150 mm, no center hole

Material Removal: 0.5 mm

Grinding Time: 3–4 minutes per piece

Wheel: Ø350 mm Resin Bond Diamond Double Disc

Coolant: Water-based

Surface burn and carbonization on wheel

Low grinding efficiency

Frequent dressing

Rough surface finish

Resin decomposes at high temperatures, damaging both bond and diamond grit.

Large contact area and no internal channels reduce coolant efficiency, leading to heat buildup.

Dense structure reduces chip clearance and heat dissipation.

Lower wheel hardness

Add surface grooves

Increase porosity

*Improves cooling and reduces burn; slightly shorter life but longer dressing intervals*

High thermal resistance and conductivity

Higher grinding efficiency for SiC

Moderate surface finish

| Feature | Resin Bond | Vitrified Bond |

|---|---|---|

| Heat Resistance | ★★☆☆☆ | ★★★★☆ |

| Thermal Conductivity | ★★☆☆☆ | ★★★★☆ |

| Surface Finish | ★★★★★ | ★★★☆☆ |

| Grinding Efficiency | ★★☆☆☆ | ★★★★☆ |

| Dressing Ease | ★★★★☆ | ★★★☆☆ |

| Usage Stage | Finish | Rough/Semi-Finish |

Illustration: Burn Mechanism & Wheel Structure Optimization

| Condition | Dressing Every 50 Pieces |

|---|---|

| Before Optimization | 4 Times |

| After Optimization | 2–2.5 Times |

Client adopted our grooved porous resin wheel. Burn significantly reduced, dressing frequency lowered by 40%. Now testing vitrified version for high-volume runs.

Grinding SiC ceramics requires high thermal control. Resin bond wheels offer excellent finish, but vitrified bonds are more robust in high-load conditions. Choosing the right wheel structure is key to consistent performance and cost-efficiency.

Need help? Contact us for customized grinding solutions and expert advice!