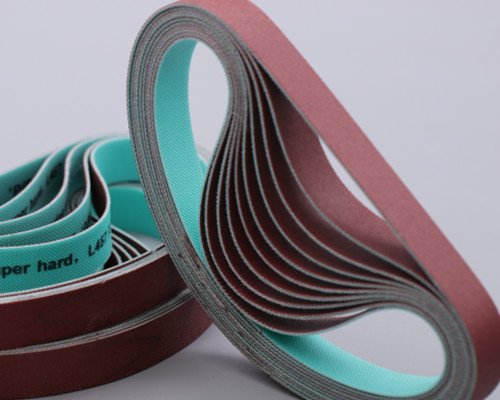

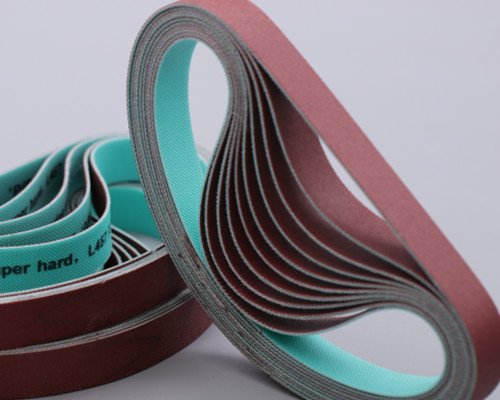

High-performance diamond abrasive belts are specially designed for precision grinding and polishing of high-hardness ceramic materials. They have excellent cutting force and wear resistance and are widely used in the rough grinding, fine grinding and mirror polishing processes of zirconia ceramics, alumina ceramics, structural ceramics, electronic ceramics and other materials.

High cutting efficiency: Diamond abrasive is sharp, with strong cutting force and high removal rate

Excellent wear resistance: High-quality nickel plating or resin binder is used, with long service life

Good surface quality: The surface of the workpiece is smooth and scratch-free after grinding, suitable for mirror processing

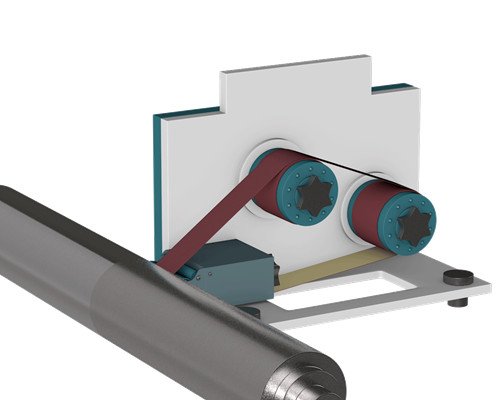

Flexible substrate: The backing is soft, suitable for a variety of belt grinders, and easy to use

Good cold grinding performance: Low temperature grinding effectively reduces the risk of thermal cracking and breakage of ceramics

| Item | Description |

| Grit Range | #60 – #3000 (From coarse grinding to mirror polishing) |

| Common Sizes | 13×457mm, 20×520mm, 50×2000mm, other sizes customizable |

| Abrasive Type | Monocrystalline Diamond / Diamond Micron Powder |

| Bond Type | Resin / Nickel Electroplated / Metal Bond |

| Backing Material | Polyester Cloth / Waterproof Paper / Ultra-flexible Fabric |

| Customization | Customizable in size, grit, bond formulation, and joint type |

| Industry | Typical Applications |

| Ceramics Manufacturing | Zirconia ceramic blades, structural ceramic components, ceramic valve plates |

| Electronics / Semiconductor | Ceramic substrates, ceramic packaging housings, circuit boards |

| Medical Devices | Dental ceramics, ceramic prosthetics, orthopedic implants |

| Aerospace | High-temperature ceramic seals, insulating ceramics, functional ceramic parts |

| Optics Industry | Optical ceramic lenses, ceramic windows, infrared components |

Precision grinding: Diamond abrasives are sharp and uniform, with stable cutting force and support for precise size control

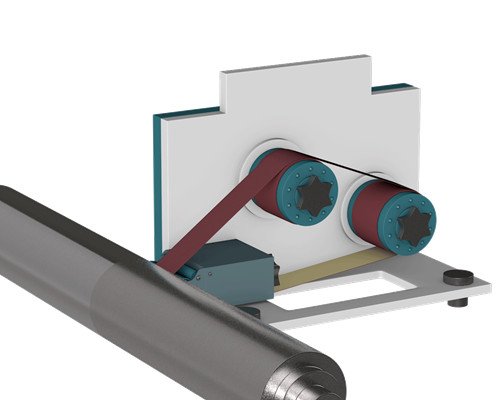

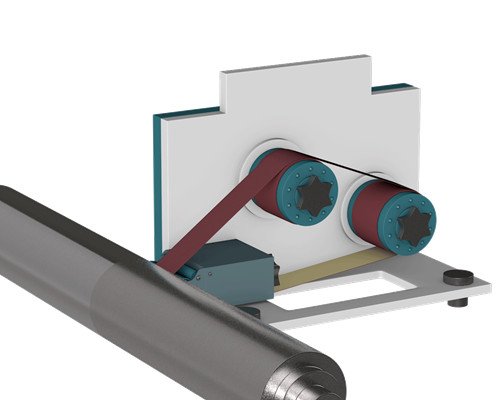

Adapt to multiple scenarios: Support dry grinding and wet grinding, suitable for processing flat surfaces, curved surfaces, special-shaped parts, etc.

Longer life: Diamond wear resistance far exceeds that of traditional abrasives, reducing the frequency of belt changes and reducing costs

Strong customization capabilities: Customized particle size, size, and binder ratio can be customized according to customer equipment and workpiece material requirements

Excellent surface treatment: From rough grinding to mirror polishing, excellent surface quality can be achieved (Ra < 0.05μm)

Diamond sanding belts play a key role in the manufacturing and maintenance of papermaking equipment. They are mainly used for precision surface grinding and finishing of the following components:

| Workpiece | Material | Processing Purpose |

| Ceramic dewatering rolls | Alumina ceramic | Surface dressing, dimension grinding, polishing |

| HVOF-coated guide rolls | Tungsten/Chromium carbide | Coating removal, roll repair, gloss improvement |

| Calendar rolls, paper guide rolls | Ceramic or carbide coatings | Surface restoration, enhanced operational stability |

| Process Type | Recommended Grit Range | Surface Roughness Ra (μm) | Features |

| Coarse Grinding | #120 – #240 | 0.6 – 1.2 | Efficient material removal, surface prep |

| Fine Grinding | #400 – #600 | 0.3 – 0.6 | Precision correction, dimension control |

| Polishing | #800 – #1500 | ≤ 0.1 | High gloss finish, reduce paper wear |