06

Aug

In the modern precision machining industry, Powder Metallurgy High-Speed Steel (PM HSS) is a critical material for tool manufacturing and high-precision part processing due to its outstanding wear resistance and high hardness. However, due to its material properties, achieving high-precision surface processing has become a key research challenge in the industry. Ceramic bond CBN grinding wheels, as superhard abrasives, offer an important solution to this problem. This case study focuses on the use of ceramic bond CBN grinding wheels to grind PM HSS, aiming to achieve the target surface roughness of Ra0.1μm.

The workpiece for this case study is powder metallurgy high-speed steel, which has a hardness of 64-66 HRC. This material is classified as a high-hardness, difficult-to-machine material, requiring highly advanced processing techniques and tool performance.

A high-precision CNC grinding machine was used for the processing, which provides precise motion control and stable processing performance, ensuring the foundation for achieving precision grinding.

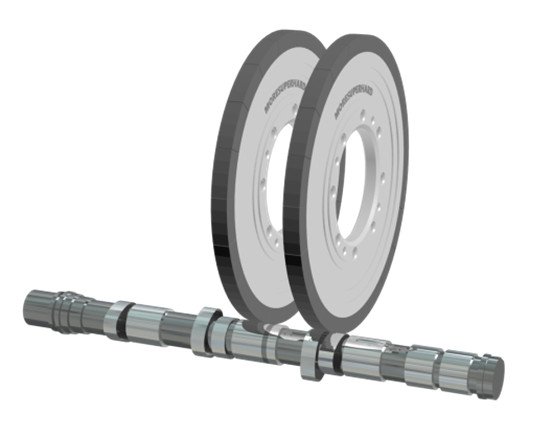

Ceramic bond CBN grinding wheels were selected for this operation, with 800# and 1200# grit sizes chosen. The 800# grinding wheel was used for rough and semi-finish grinding, while the 1200# wheel was intended for finish grinding, aiming to achieve the desired roughness by combining different grits.

When using the 800# ceramic bond CBN grinding wheel, the actual surface roughness achieved was Ra0.2μm. Both the grinding efficiency and wheel lifespan met the customer’s expectations. Although the surface finish was acceptable, it still fell short of the target Ra0.1μm, indicating that the 800# grinding wheel had limitations in further reducing surface roughness.

Upon initial use of the 1200# grinding wheel, after correction, the wheel showed good grinding results with an ideal surface finish. However, as the grinding continued, the grinding wheel started to experience “grinding failure” during the processing of the second part. Ultimately, the surface quality did not meet expectations, and the actual roughness was also Ra0.2μm. This indicates that while the 1200# grinding wheel initially performed well, it experienced stability issues during prolonged grinding.

Upon in-depth analysis, it was found that the main issue with the 1200# grinding wheel was its high hardness. When grinding high-hardness materials like PM HSS, the high hardness of the grinding wheel caused the cutting edges to quickly become dull, losing their cutting ability. Moreover, the high hardness of the wheel led to significant heat generation and friction during grinding, accelerating the wheel’s wear rate and affecting processing accuracy and surface quality.

Ceramic bond CBN grinding wheels have become increasingly popular in metalworking, especially for grinding hard materials. Their key advantages include:

This case study on grinding powder metallurgy high-speed steel highlights the significant impact of the grinding wheel grit, hardness, and equipment parameters on grinding performance. In practical applications, selecting the appropriate grinding wheel specification and optimizing processing parameters are key to achieving high-precision, high-efficiency grinding. Moving forward, Moresuperhard will continue to refine grinding technologies and optimize products and services, providing customers with better, more tailored grinding solutions to help the precision machining industry reach new heights.