22

Jul

In the realm of precision engineering, there exists a “divine tool” known as the PCD micro-edge milling cutter. Like a master sculptor with supernatural skills, it effortlessly slices through aluminum alloys as if cutting tofu, while etching nanoscale intricate patterns on carbon fiber and plastics. Today, we unveil the mysteries of this “industrial scalpel.”

PCD micro-edge milling cutters boast an exceptionally broad application spectrum. For hard and brittle materials like sapphire, glass, and ceramics, they achieve precision finishing with surface roughness (Ra) below 0.08μm. When processing titanium alloys or aluminum alloy components, they not only deliver precision finishes but also eliminate vertical tool marks left by conventional cutters.

Breaking through the limitations of traditional tool materials and processing techniques, this innovative tool represents a new generation of small-diameter helical-edge cutters for hard materials. It excels in milling non-ferrous metals (aluminum, copper, titanium, magnesium alloys, etc.) and non-metallic materials (carbon fiber composites, graphite, ceramics, quartz, etc.), delivering high precision, long tool life, and efficiency across advanced manufacturing scenarios. It enables energy-saving, environmentally friendly, and ultra-precise modern production.

PCD (Polycrystalline Diamond) is not merely a substitute for natural diamonds but a marvel of 20th-century materials science. Scientists blend micron-sized diamond particles (comparable to flour granules) with cobalt-nickel metal powders, then subject the mixture to extreme conditions: 1,400°C and 500,000 atmospheres of pressure (five times the pressure at the Mariana Trench). This process sintters the material onto a tungsten carbide substrate, creating a composite with unparalleled hardness (8,000–10,000 HV) — three times harder than cemented carbide. This “bulletproof vest” for tools ensures minimal wear even after 300 hours of continuous aluminum alloy cutting.

Micro-Edge: Nanoscale Precision Carving

The true innovation lies in its nanoscale edge. Traditional cutters have edge radii of 10–50 microns, while PCD micro-edge cutters achieve 0.5–5 microns — roughly 1/100th the diameter of a human hair. Imagine slicing aluminum with a blade thinner than a razor, leaving a mirror-like finish so flawless that water-based cutting fluids are avoided (to prevent pinholes), requiring only kerosene or diesel as lubricants.

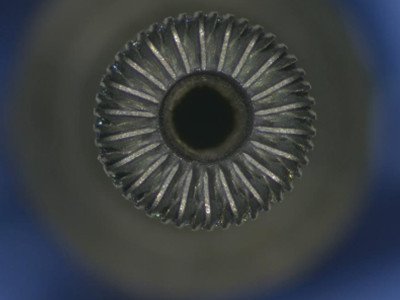

Its multi-edge design (e.g., 44-flute configurations) further enhances efficiency, boosting productivity by over 40% compared to single-edge tools — akin to 44 skilled ballerinas dancing in unison.

A leading flagship smartphone’s aluminum frame is shaped entirely by PCD micro-edge cutters. During roughing, high-speed feed rates (20,000 RPM, 5 m/min) rapidly profile the part. Finishing removes just 0.02mm per pass, achieving Ra 0.1μm — 10 times smoother than A4 paper. Tool changes are eliminated, boosting yield rates from 85% to 99%.

Recent lab breakthroughs use laser-assisted precision grinding to create PCD micro-mills with 0.2-micron edge radii — capable of etching QR codes on human hairs. These tools may soon enable ultra-thin laptops and foldable phones, hiding microscopic masterpieces in everyday devices.

(Pro Tip: Treat these tools like high-performance sports cars. After use, clean thoroughly with ultrasonic systems. If edges dull, resharpen immediately — even diamonds can’t withstand brute force.)