Our Ceramic Milling Cutters are designed specifically for high-temperature alloys such as superalloy GH4169. These tools offer superior performance in machining high-performance materials that require extreme cutting conditions, such as in aircraft engines. With advanced ceramic technology, these cutters increase machining efficiency by up to 15–20 times compared to traditional tools, delivering faster cutting speeds, higher tool longevity, and improved surface quality.

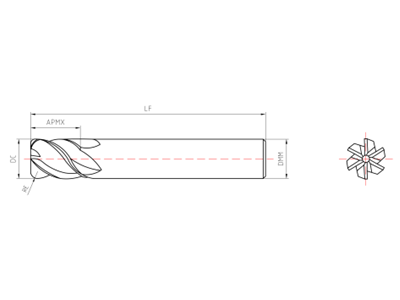

| Model | Cutting Diameter (DC) | Nose Radius (RE) | Max Depth of Cut (Apmx) | Shank Diameter (DM) | Total Length (LF) | No. of Teeth (ZEFP) |

|---|---|---|---|---|---|---|

| 0605W | 6 mm | 1 mm | 5 mm | 6 mm | 60 mm | 4/6 |

| 0806W | 8 mm | 1 mm | 6 mm | 8 mm | 60 mm | 4/6 |

| 1008W | 10 mm | 1.5 mm | 8 mm | 10 mm | 65 mm | 4/6 |

| 1209W | 12 mm | 1.5 mm | 9 mm | 12 mm | 70 mm | 4/6 |

| 1610W | 16 mm | 2 mm | 10 mm | 16 mm | 83 mm | 4/6 |

| 2010W | 20 mm | 4 mm | 10 mm | 20 mm | 83 mm | 4/6 |

| Model | Cutting Speed (m/min) | Feed per Tooth (mm/z) | Depth of Cut (ap, mm) | Width of Cut (Ae, mm) | Cutting Speed (m/min) | Feed per Tooth (mm/z) | Depth of Cut (ap, mm) |

|---|---|---|---|---|---|---|---|

| 6 | 400-800 | 0.02-0.04 | ≤4.5 | ≤0.6 | 400-800 | 0.02-0.04 | ≤1.2 |

| 8 | 400-800 | 0.02-0.04 | ≤6 | ≤0.8 | 400-800 | 0.02-0.04 | ≤1.6 |

| 10 | 400-800 | 0.04-0.07 | ≤7.5 | ≤1 | 400-800 | 0.04-0.07 | ≤2.0 |

| 12 | 400-800 | 0.04-0.07 | ≤9 | ≤1.2 | 400-800 | 0.04-0.07 | ≤2.4 |

| 16 | 400-800 | 0.04-0.07 | ≤10 | ≤1.6 | 400-800 | 0.04-0.07 | ≤3.2 |

| 20 | 400-800 | 0.04-0.07 | ≤10 | ≤2 | 400-800 | 0.04-0.07 | ≤4 |

These ceramic milling cutters are primarily used in machining high-temperature alloys like superalloys (e.g., GH4169), ideal for demanding environments such as aerospace, automotive, and high-performance engine components.

For more information or to place an order, contact us today!

| Workpiece Material | Superalloy GH4169 |

|---|---|

| Machine | HAIMER (HSK63 Hydraulic Tool Holder) |

| Cooling Method | No Cooling |

| Processing Type | Side Milling |

| Cutting Parameter (n) | 13,270 rpm |

| Feed Rate (F) | 3,600 mm/min |

| Depth of Cut (Ap) | 9 mm |

| Width of Cut (AE) | 0.6 mm |