20

Aug

Optical products are actually very common in our daily lives, ranging from simple applications like glasses, camera lenses, and security cameras, to large-aperture applications such as optical lenses for remote sensing satellites, astronomical telescopes (Hubble and Webb), large optical telescopes, and lenses for weapon electro-optical pods. We are constantly enriching our product offerings and expanding their applications. Technological breakthroughs enable us to constantly push the boundaries of our processes to meet more demanding and stringent application scenarios. Market demand, in turn, drives us to continuously iterate and update our technologies to create more and more incredible products.

Today, we’ll take you through the entire cold working process for lenses. Curious readers may already be asking, what is cold working? Is there also hot working? Just a reminder, the “cold” here doesn’t mean sub-zero temperatures. Optical cold working refers to the process of precisely processing optical blanks (such as blocks, profiles, and pressed parts) into optical components of the desired shape, size, and surface quality by removing material through mechanical cutting, grinding, and polishing, without changing the physical state of the optical material (primarily glass, crystal, etc.) (i.e., without melting or softening it).

The specific process for optical lens manufacturing is: rough grinding – fine grinding – grinding/polishing – cleaning – core extraction – coating – gluing – coating – inspection – packaging – and shipping. While each company’s procedures and naming conventions may vary slightly, the general process is as follows. As you can see, optical lens manufacturing is a precise, multi-step process, with each link crucial and directly impacting the final lens’ optical performance and quality. No single step can afford to go awry.

Below, we’ll explain each process step by step. While the information is quite extensive, if you’re feeling overwhelmed, save this as your optical dictionary and refer back to it when needed.

This is the first step in lens forming. Using a relatively coarse diamond grinding wheel, a large amount of excess material is quickly removed from the raw material (usually a glass or resin preform, such as a round cake, square, or molded blank) based on the lens design (radius of curvature, diameter, center thickness, etc.), resulting in a rough lens that approximates the target shape and dimensions.

The goal is to efficiently remove material to achieve the basic lens geometry (spherical or aspherical profile) in preparation for subsequent finishing. The surface is very rough at this stage.

Following the rough grinding process, a diamond grinding wheel with a finer grit (finer than the rough grinding grit) is used for further processing. This allows for further precise control of the lens’ radius of curvature, center thickness, edge thickness, and surface profile, bringing it closer to the final design size and shape.

Purpose: To improve the lens’s geometric accuracy and surface finish. During this process, the lens is typically still opaque, laying a good foundation for the lapping process and reducing the amount of material removed and the time required for lapping.

This is a critical step in achieving an optical surface. A polishing slurry (polishing slurry) consisting of a mixture of abrasives (such as cerium oxide, aluminum oxide, or diamond powder), water, or oil, and a specific lapping mold (typically made of asphalt, polyurethane, or a synthetic material) are used. The lens is polished along the lapping mold using a specific motion path.

The goal is to remove subsurface damage left by fine grinding, eliminate surface irregularities, and achieve a smooth and transparent lens surface, achieving extremely high surface accuracy (such as f-number and local aperture) and surface roughness requirements. The lens surface should approach final optical quality after lapping.

After grinding and before subsequent critical steps (such as coating and gluing), lenses are thoroughly cleaned. This process utilizes a combination of specialized cleaning agents (alkaline, acidic, or neutral), ultrapure water, ultrasonic cleaning machines, megasonic cleaning machines, spraying, rinsing, and dehydration and drying (such as centrifugal drying, IPA vapor drying, or hot air drying).

The goal is to completely remove all contaminants from the lens surface, including grinding dust, grease, fingerprints, dust particles, and cleaning agent residue. Achieving extremely high cleanliness standards (typically performed in a cleanroom environment) is crucial for ensuring the quality and adhesion of subsequent steps, especially coating. Any trace of residue can lead to coating defects or delamination.

Using a precision edge grinder, the lens’ outer diameter is precisely ground to the desired frame or assembly requirements, and specific angles (chamfers) or shapes (such as safety chamfers and slimming chamfers) are ground onto the lens edge.

This step serves multiple purposes, but mainly three:

· Dimensional alignment: This ensures that the lens’ optical center (or designated reference point) precisely aligns with the mechanical center (outer diameter center). This is crucial for the concentricity and image quality of the assembled optical system (such as a lens assembly). This is the most important purpose.

· Assembly fit: This ensures that the lens diameter is precisely machined to the dimensions required for assembly.

· Protection and aesthetics: This removes sharp edges to prevent chipping, scratches on operators or assembly components, and sometimes also improves appearance.

In an ultra-high vacuum environment, one or more layers of very thin, transparent optical films are deposited on one or more surfaces of a lens using methods such as physical vapor deposition (e.g., vacuum evaporation, sputtering) or chemical vapor deposition.

Purpose:

Anti-reflection coating: The most common method, it reduces reflection losses on the lens surface through light interference, increasing light transmittance and reducing glare and ghosting.

Beam-splitting coating: Splits incident light into reflected and transmitted light in a specific ratio.

Reflective coating: Increases the reflectivity of light of specific wavelengths (e.g., a reflector).

Filter coating: Selectively transmits or blocks light of specific wavelengths.

Other functional coatings: These include waterproof coatings, anti-fog coatings, anti-static coatings, and the base layer of wear-resistant coatings (hardened coatings). These coatings are applied based on the specific requirements of the lens.

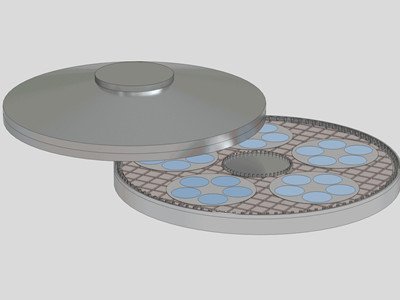

This step isn’t required for all lenses, but is primarily used for bonded lenses consisting of multiple lenses. Using optical-grade transparent adhesives, such as UV-curable adhesives or heat-curable epoxy resins, two or more lenses with specific optical designs are bonded together using precision centering equipment. The bonding surfaces, typically concave and convex, are bonded together to form a single, integrated component.

Bonded lens design objectives

Eliminating air interfaces: Reduces reflection loss and stray light within the lens assembly.

Correcting aberrations: Utilizes the combined optical properties of different glass types to correct for aberrations such as chromatic aberration.

Simplifying assembly: Securing multiple components into a single unit facilitates subsequent assembly and adjustment.

Protecting sensitive surfaces: Surfaces susceptible to scratching or corrosion are protected within the bonded layer.

Lens inking is a specific, optional process step in optical lens manufacturing. It is primarily used in optical systems requiring extremely high image quality or special functions, such as lenses in high-end camera lenses, microscope objectives, telescopes, and laser systems. Some lenses are also called “ink,” meaning they have an edge-coated, improved overall performance.

·Process: A special light-absorbing black coating, typically matte black paint, epoxy containing carbon black, black anodizing, or a special black ceramic coating, is applied to the non-optically functional areas of the lens, primarily the sides/circumference, and sometimes also to the chamfered surfaces near the edge or the non-transmissive areas of the lens base.

·Critical Position: Inking is strictly avoided within the lens’s effective optical transmission area, i.e., surfaces where light must pass through or reflect, and is performed only in areas of contact with mechanical structures.

The primary purpose of inking is to eliminate or minimize stray light, thereby improving the image quality and signal-to-noise ratio of the optical system.

Inspection occurs throughout the entire production process, but final, comprehensive quality control is performed after all lens processing is complete. A variety of precision optical, geometric, and appearance testing instruments and equipment are used.

Purpose: To ensure that lenses fully meet design specifications and customer requirements. Key inspection items include:

Optical performance: focal length, refractive power, aberrations (spherical aberration, coma, astigmatism, field curvature, distortion, chromatic aberration), transmittance, reflectivity, wavefront aberration, etc.

Geometric dimensions: radius of curvature, center thickness, edge thickness, diameter, surface accuracy (aperture, local error), decentration (after core removal).

Surface quality: surface finish (roughness), scratches, pitting (graded according to national standards, military standards, or ISO standards), edge chipping, cracks, open bubbles, etc.

Plating/Coating quality: film color, uniformity, adhesion, abrasion resistance, water and oil repellency, etc.

Appearance inspection: stains, foreign matter, bubbles (in case of laminated lenses), edge chipping, etc. Material properties: refractive index, Abbe number, stress birefringence, bubble impurity content, etc. (usually tested at the raw material or rough grinding stage).

Qualified lenses are packaged according to customer specifications or internal standards using appropriate packaging materials and methods (such as anti-static bags, foam pads, lens cases, vacuum packaging, desiccant, shockproof boxes, etc.). Labels containing information such as product name, specifications, batch number, and inspection status are affixed. After completing warehousing and shipping procedures, the finished products are safely delivered to customers through logistics.

In short, optical lens processing is a highly precise and interconnected process.From the initial blank shaping (rough grinding and fine grinding), to obtaining the optical surface (grinding and cleaning), to precise positioning and sizing (core extraction), and then through coating and film coating to impart various functional properties. For composite lenses, they also require gluing. Finally, rigorous quality inspection is carried out to ensure that the lenses are properly packaged for shipment.