21

Aug

In industrial manufacturing, precision grinding of silicone materials has always faced numerous technical challenges. This article will delve into the structural secrets of electroplated diamond grinding wheels, focusing on their micro-structural characteristics. Furthermore, it will demonstrate their exceptional performance in silicone grinding using practical examples.

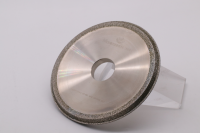

1.Micro-structure Analysis: Unique Advantages of Electroplated Grinding Wheels

Through electron microscope observation, at 60 times magnification, the electroplated diamond grinding wheel shows the following key structural features:

✔ Coating bonding characteristics: The metal coating forms a metallurgical bonding interface with the substrate, and the bonding strength is significantly better than that of traditional processes, effectively preventing the abrasive from falling off prematurely (left picture);

✔ Abrasive distribution characteristics: Diamond abrasives are evenly embedded in the metal coating, with reasonable particle spacing. This structure ensures stability and processing efficiency during grinding (right figure);

2.Customer pain point: limitations of traditional grinding wheels

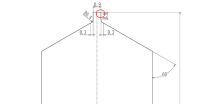

A customer faced a special processing requirement in the production of silicone products: they needed a special grinding wheel with a 0.9mm wide convex edge and relatively loose surface accuracy requirements. When initially using a vitrified bond grinding wheel, they encountered the following problems:

✔Unstable processing quality;

✔Frequent grinding wheel replacement;

✔Long equipment downtime;

✔Comprehensive production costs remain high.

The comparison between vitrified bond grinding wheel and electroplated diamond grinding wheel is as follows:

| Characteristic | Vitrified bond grinding wheels | Electroplated diamond grinding wheel |

| Abrasive Type | Ordinary abrasives (corundum, silicon carbide) | Super-hard abrasives (diamond/CBN) |

| Binder | Glass-phase ceramics(Al₂O₃-SiO₂) | Metal plating layer (nickel/nickel-cobalt alloy) |

| Abrasive distribution | Random distribution of multiple abrasive layers | The single abrasive layer is arranged in an orderly manner, dense and pore-free |

| Combination method | High temperature sintering chemical bonding | Electroplating machinery-metallurgical composite bonding |

3.Technological breakthrough: Advantages of electroplated diamond grinding wheels

Electroplated diamond grinding wheels use metal plating to attach diamond abrasives directly to the surface of the metal substrate, which has the following significant advantages:

✔Flexible shape customization: It can be easily made into various non-standard shapes to perfectly fit the special edge structure required by customers;

✔High grinding efficiency: Diamond is a super-hard material, and its efficiency is significantly improved when grinding silicone materials.;

✔Long service life: Compared with traditional grinding wheels, the service life is greatly extended and the replacement frequency is reduced.

Although the use of coarser diamond grit will result in rounded corners (circled in the figure), this slight compromise is completely acceptable because the customer does not require high precision.

4.Actual effect: comprehensive improvement of production efficiency

After switching to the electroplated diamond grinding wheel solution, the customer’s production line has experienced a qualitative leap:

✔Significantly increased service life: The frequency of grinding wheel replacement is significantly reduced;

✔Reduced downtime: significantly increased equipment availability;

✔Grinding efficiency is significantly improved: production cycle is significantly shortened;

✔Comprehensive cost reduction: achieving a win-win situation in quality and cost;

5.Industry Inspiration: Decision-making Ideas for Optimizing Processing Solutions

This success case offers an important lesson: there’s no “best” grinding wheel, only the “most suitable” one. When machining specialized materials, traditional methods shouldn’t be relied upon. While electroplated diamond grinding wheels are more expensive, they offer a more economical option when considering overall production efficiency, equipment utilization, and overall cost. Especially for difficult-to-machine materials like silicone, super-hard grinding wheels often deliver unexpected results.

With the advancement of materials science, electroplated diamond grinding wheels will shine in more fields in the future. For companies facing similar grinding problems, it is recommended to consider this innovative solution, which may help them find the key to breaking through production bottlenecks.

Are you facing challenges processing unique materials? Share your specific needs with us and let’s discuss the best solutions.