28

Oct

There is a wide variety of rotating parts. Taking wind power equipment as an example, a single wind turbine includes main bearings, pitch bearings, yaw bearings, and generator component bearings, and is usually equipped with 32 bearings of different specifications.

In addition, wind power main shafts, gear rings, gear shafts, and tower barrels all fall into the category of rotating parts.Most of these parts are made of alloy steel, while the main shafts of large-megawatt wind turbines may also use cast iron materials.

Lathes are the most widely used equipment for processing rotating parts. Among them, large bearings, gear rings, and tower barrels are usually processed by vertical lathes, while large shaft parts are mostly processed on horizontal lathes.

The machining solutions for rotating parts cover the application of a variety of high-efficiency cutting tools, including heavy-duty milling, thread machining, profile copying, and hole system machining.

Rough Turning of Cylindrical Surfaces, End Faces and Inner Holes

We offer a variety of heavy-duty inserts such as SN25 and CN19, equipped with a wide range of chip breaker geometries (e.g., R, RM, NR, HR2). The carefully designed chip breakers ensure smooth chip evacuation. Adopting advanced coating technology, these inserts are suitable for high-feed and dry cutting applications, achieving excellent metal removal rates.

Machining of Gear Ring Ball Grooves

We provide design solutions for standard and non-standard groove profiles. When rough machining grooves, we recommend using RCMT round inserts to achieve excellent chip-breaking performance and high production efficiency.

Machining of Bolt Holes

U-drills can replace traditional drill bits, doubling the number of holes drilled in the same time and significantly improving production efficiency and hole quality.

Machining of Large Threaded Holes on End Faces

We provide uniquely customized large taps for wind power applications. This product currently has sufficient stock in China, with no waiting time required.

A large proportion of rotating parts need to be processed through heavy-duty turning. The machining conditions are usually harsh: there is often scale residue on the workpiece surface, accompanied by high cutting forces and high cutting temperatures. Therefore, the requirements for tool performance are extremely stringent.

As shown in the figure, the maximum swing diameter of this wind power main shaft is 2.2 meters, with a total length of 5.5 meters. It is made of 42CrMo material, and the machining allowance reaches 20mm.

forging defects and meet the customer’s demand for efficient production, a large-allowance machining solution is required.

Our tool solution is designed with a cutting edge length range of 25-50mm, the maximum single-edge cutting depth can reach 36mm, and positive/negative rake angle options are available.

With its large cutting depth and reinforced cutting edge design, a metal removal rate of 1,500 kg/h (i.e., 1.5 tons per hour) is achieved. This is equivalent to processing a volume of metal equal to the weight of a family car per hour, which places strict requirements on tool performance:

It must have excellent impact resistance to prevent tool body damage caused by fracture during cutting;

It must maintain high wear resistance and reliable chip-breaking ability, especially for the open machining environment of large parts, to effectively control the risk of iron chip splashing.

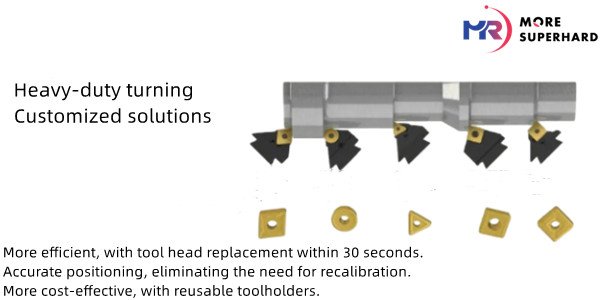

In addition to conventional tool holders, we offer tool solutions with modular replaceable tool heads, featuring the following advantages:

Efficiency

It enables seamless switching from rough machining to finish machining. There is no need to disassemble the tool body; the switch can be completed simply by replacing the tool head, which significantly shortens tool change time and reduces labor intensity.

Cost-Effectiveness

It greatly reduces the inventory demand for expensive tool bodies and the cost of insert consumption – when the tool head is damaged, there is no need to replace the entire tool body. For example, tool bodies of sizes 50 and 60 (e.g., model specifications like 50mm/60mm diameter) can be reused.

The figure above shows a slewing bearing. Among its components, the tool holder on the right is used for rough turning the inner hole; the left side adopts a composite design of an end face turning tool and a cylindrical turning tool. With a single clamping, the entire process can be completed without replacing the tool post or tool holder. For difficult-to-machine materials (such as surface-hardened layers or high-tensile-strength materials), we use a double-screw clamping structure, which can significantly improve the clamping stability of the insert.