The brake disc is a core component of the vehicle’s braking system, converting kinetic energy into heat energy to ensure safe deceleration and stopping.

Among various brake disc materials — cast iron, aluminum alloy, and composite — carbon ceramic composites (CCB) have become the preferred choice for high-performance vehicles due to their light weight, exceptional heat resistance, and superior durability.

However, machining carbon ceramic materials is highly challenging due to their extreme hardness, brittleness, and unique thermal properties.

Conventional abrasives like alumina or silicon carbide cannot effectively process such materials.

Diamond grinding wheels are the only reliable and efficient solution for machining carbon ceramic brake discs, providing superior sharpness, precision, and tool life.

| Performance | Cast Iron Brake Disc | Carbon Ceramic Brake Disc |

| Weight | Normal | 40–50% lighter |

| Heat Fade | Significant | Almost none |

| Max Operating Temperature | ~700°C | >1300°C |

| Corrosion Resistance | Poor | Excellent |

| Cost | Low | High |

| Application | Standard vehicles | High-performance, racing, and EVs |

Choosing the right bond type is crucial for achieving balance between efficiency, precision, and wheel life.

| Features | Resin Bond Diamond Wheel | Vitrified (Ceramic) Bond Diamond Wheel |

| Elasticity / Damping | Excellent – reduces vibration, improves surface finish | Rigid – high machine stability required |

| Heat Resistance | Moderate – suitable for mid-temp operations | High – ideal for heavy-duty, high-temp environments |

| Grinding Efficiency | High – fast cutting, quick self-sharpening | High – longer life, stable precision |

| Shape Retention | Moderate | Excellent |

| Cost | Lower | Higher |

| Suitable Application | Small batch, fine finishing, low-medium temperature polishing | Mass production, high precision, automation, heavy-duty grinding |

| Durability | Shorter life, frequent dressing | Longer life, less dressing required |

| Shock / Vibration Resistance | Good | Fair |

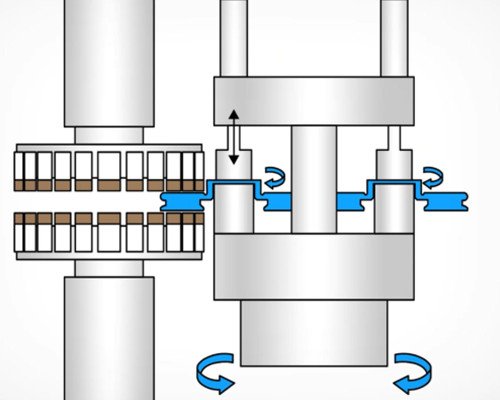

Low grinding forces thanks to sharp tools

Uniform surface results

Maximum service life

Short cycle times and high efficiency

Compatible with automated and CNC grinding systems

Carbon ceramic brake disc grinding

High-performance automotive and racing brake systems

Carbon-SiC composite components

Aerospace friction materials

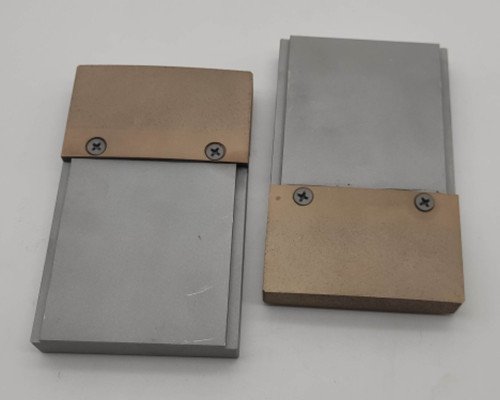

Application: Grinding carbon ceramic brake discs

Requirement: Dimensional tolerance ±0.02 mm, surface roughness Ra ≤ 0.8 µm

Process setup:

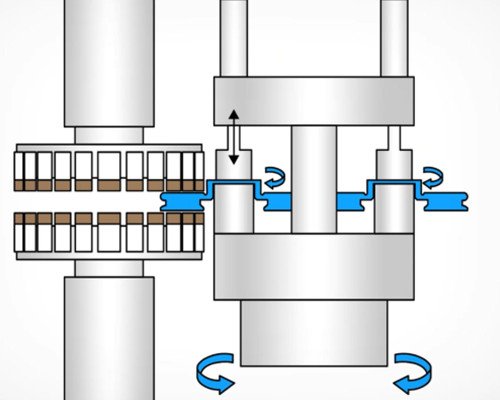

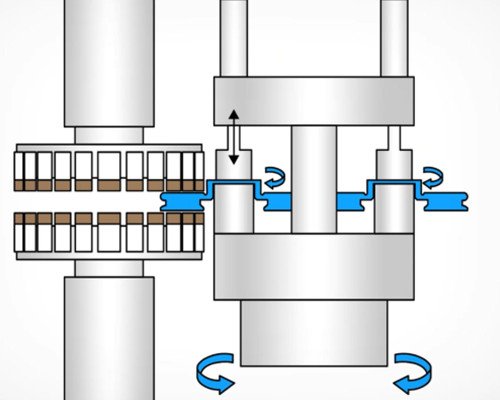

Coarse grinding: Resin diamond wheel (W80) – efficient stock removal

Fine grinding: Vitrified diamond wheel (W120) – precision and consistency

Dressing cycle: Every 500 pieces

Results:

Grinding efficiency: +15%

Wheel life: +30%

Qualified rate: 98%

Customer feedback:

“The new wheel solution made our CCB discs lighter, more durable, and race-ready with stable braking performance.”