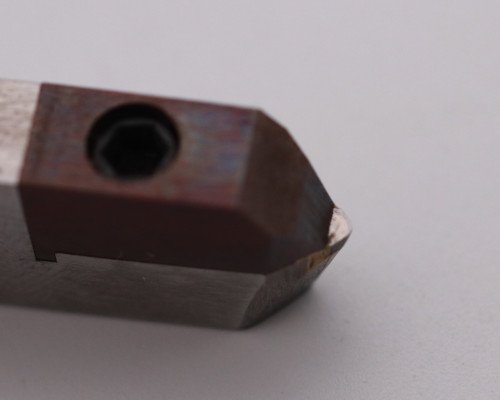

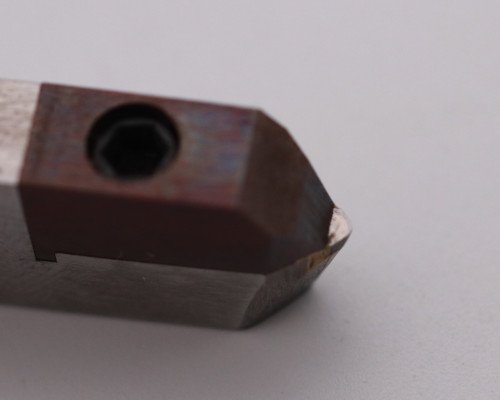

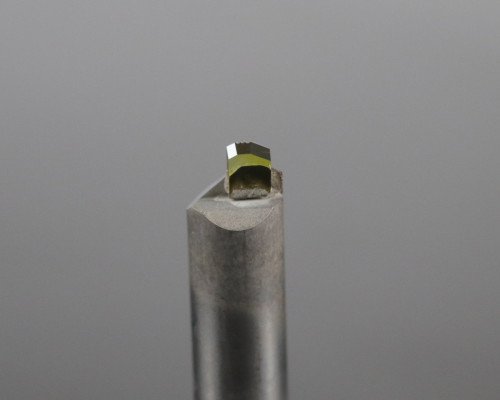

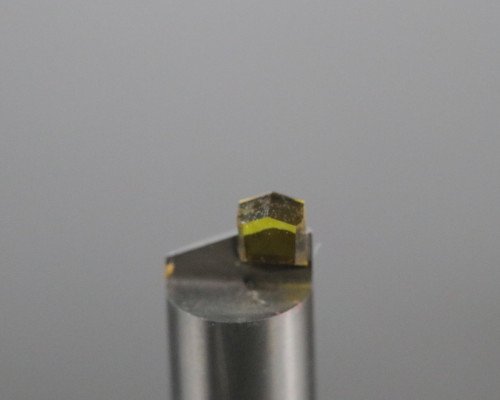

The MCD Posalux Tool is a high-precision cutting tool engineered to deliver outstanding surface finish and accuracy.

It is specially designed for ultra-fine machining tasks that demand superior dimensional control and mirror-like surface quality.

Through advanced diamond processing and manufacturing technology, this tool ensures stable performance and exceptional durability across various complex materials.

| Item | Details |

|---|---|

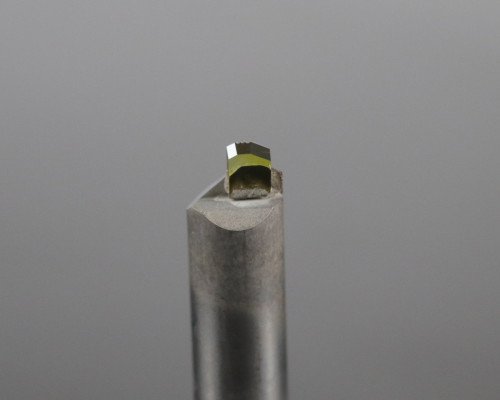

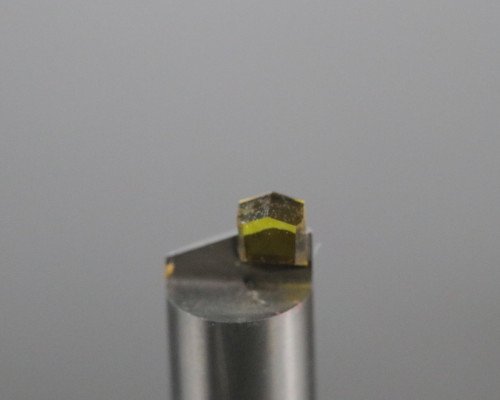

| Tool Tip Material | Natural Diamond, MCD (Monocrystalline Diamond), CVD (Chemical Vapor Deposition) Diamond, PCD (Polycrystalline Diamond) |

| Tool Tip Width | 0.25mm – 10mm |

| Tool Body Material | Iron, Stainless Steel, Tungsten Steel |

| Applicable Equipment | Rose Engraving Machines, CNC Automatic Machining Equipment |

| Machinable Materials | Gold, Silver, Copper, Aluminum, Acrylic, and other non-ferrous or soft materials |

Used for engraving and machining precious metals and gemstones, enabling detailed patterns and artistic designs that enhance product value and aesthetic appeal.

Applied in the fabrication of optical lenses, prisms, and reflective components, ensuring superior surface quality and optical clarity.

Ideal for machining miniature precision components such as watch parts, micro-mechanical elements, and sensor housings,

where accuracy and surface finish are critical.

The MCD Posalux Tool combines precision engineering with advanced diamond technology,

making it an essential choice for industries that require high-performance micro-machining — from jewelry to optics and fine mechanical components.