Brass is a tough and ductile non-ferrous metal that often causes wheel loading, chip adhesion, and heat-related burn during grinding. The resin bond diamond grinding wheel is the ideal solution for machining brass thanks to its excellent elasticity, sharp cutting ability, and resistance to clogging.

It ensures stable grinding performance, long service life, and superior surface finish for both roughing and finishing operations.

✔ Excellent Self-Sharpening

Resin bond provides natural elasticity and maintains sharp cutting edges, minimizing the risk of wheel loading.

✔ Reduced Heat Generation

Efficient chip evacuation and good thermal conductivity of diamond help prevent surface burn on brass workpieces.

✔ Smooth Cutting & Low Force

Ideal for non-ferrous metals, allowing fast feed rates and small depths of cut without causing work hardening.

✔ High-Porosity Structure Available

Optional large-pore structure or pore-forming additives significantly improve chip removal when grinding sticky materials like brass.

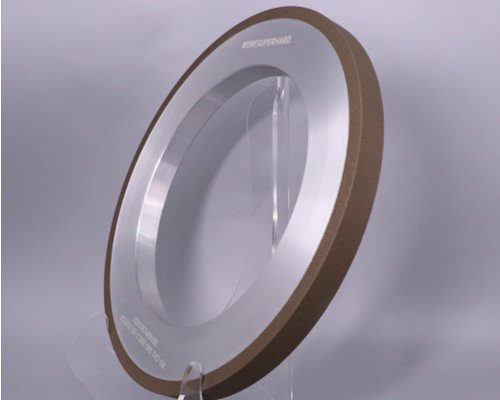

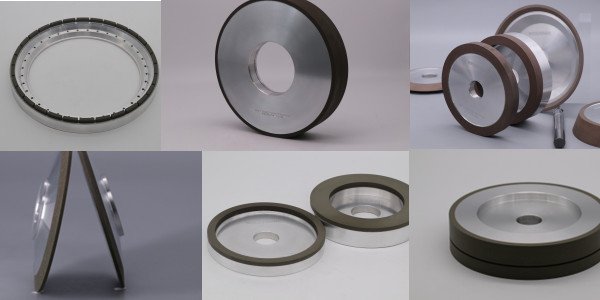

✔ Custom Shapes & Sizes

Available in all standard and non-standard forms to fit surface grinders, CNC grinders, and profile grinders.

| Category | Options / Recommended Range | Notes |

|---|---|---|

| 1. Abrasive | Synthetic Diamond (RVD Series) | High toughness and strong self-sharpening; ideal for non-ferrous metal grinding. |

| 2. Grit Size | Rough Grinding: 100# – 180#

Finishing: 240# – W40 |

Avoid overly fine grits to prevent wheel loading. |

| 3. Bond Type | Resin Bond (B) – Recommended

Optional: Hybrid Bond |

Resin offers elasticity and anti-loading performance; hybrid provides longer life and higher precision. |

| 4.Concentration | 50% – 75% | 75% is a popular and balanced option. |

| 5. Wheel Shapes | 1A1 Flat Wheel 6A2 Cup Wheel 11A2 Bevel Cup Wheel 12A2 Dish Wheel Custom shapes available | Select based on machine type and workpiece geometry. |

| 6. Sizes | Diameter: 100–400 mm Thickness, abrasive layer width, and bore size customizable | Full customization supported for OEM orders. |

| Parameter | Recommended Range | Notes |

|---|---|---|

| Wheel Speed | 20–35 m/s | Higher speed improves efficiency as long as burning is avoided. |

| Feed Rate | 10–25 m/min | Faster feed helps prevent adhesion and reduces heat buildup. |

| Depth of Cut | Roughing: 0.01–0.03 mm

Finishing: 0.002–0.01 mm |

Use “small depth, fast feed” strategy to avoid loading and surface damage. |

| Coolant | Water-based emulsion or synthetic coolant | Mandatory for cooling, lubrication, and chip evacuation. |

Resin diamond grinding wheel for brass is suitable for:

Precision brass components

Brass valve parts

Connectors and electronic components

Hardware parts

Optical and instrumentation brass pieces

Mold inserts made of brass

Automotive and aerospace non-ferrous metal parts

Precision Hardware Factory (Germany)

Workpiece: Brass valve seat

Problem: Poor surface finish and high grinding temperature

Solution: 1A1 resin diamond wheel, 240#

Result:

Grinding temperature dropped significantly

No surface burn

Wheel life increased by 35%