01

Dec

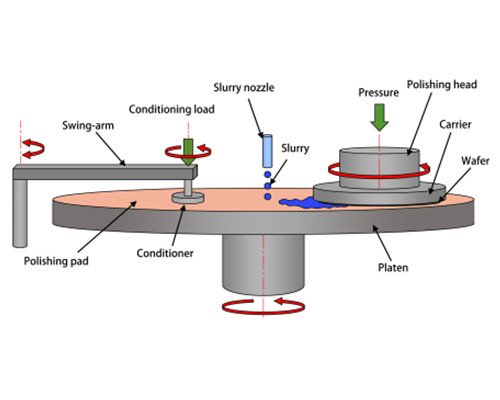

(1) Effectively and evenly deliver polishing slurry to different areas of the polishing pad;

(2) Smoothly remove reactants, debris, etc. after polishing;

(3) Maintain the polishing slurry film on the surface of the polishing pad so that the chemical reaction can proceed fully;

(4) Maintain the stability of the polishing process and prevent surface deformation so as to obtain a better surface morphology of the substrate.

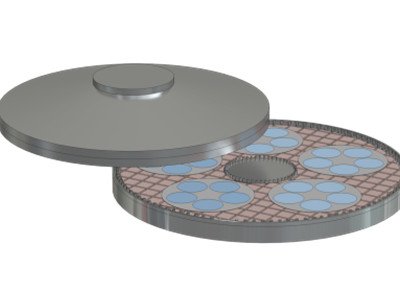

Polishing pads can be classified according to whether they contain abrasives: abrasive polishing pads and abrasive-free polishing pads. Abrasive-free polishing pads are typically used for polishing sapphire substrates.

Polishing pads can be classified according to their material into three main types:

① Polyurethane polishing pads.

② Non-woven fabric polishing pads.

③ Composite polishing pads.

External dressing of polishing pads requires the use of external dressing tools for offline or online dressing.

Diamond is the commonly used material for polishing and finishing sapphire substrates.

1. The effect of polishing pads on the polishing effect of sapphire substrates is reflected in the material, structure, hardness, compressibility, filler content, and roughness of the polishing pad. Polyurethane polishing pads are more suitable for polishing sapphire substrates. The greater the hardness of the polishing pad, the stronger its pressure resistance, the better the flatness of the ejected substrate, and the greater the polishing efficiency. The greater the surface roughness of the polishing pad, the greater the polishing efficiency.

2. Appropriately groove the surface of the polishing pad to homogenize the dynamic pressure distribution on the substrate surface, thereby improving the polishing effect. The width of the polishing pad grooves should be appropriate; if it is too small, the grooving effect will not be apparent, and if it is too large, the polishing efficiency will decrease, and the roughness of the substrate will also deteriorate. The depth of the polishing pad grooves has no significant impact on the polishing effect. The spiral direction of the polishing pad grooves should be consistent with the rotation direction of the polishing disc to avoid excessive polishing fluid being thrown out due to reverse rotation, which would reduce the polishing efficiency.

3. During use, the polishing pad for sapphire substrates can be effectively removed using a diamond dresser, restoring uniform micropores to the surface and achieving a better polishing effect.

4.Polyurethane polishing pads are more suitable for use as polishing pads for sapphire substrates. Experiments showed good polishing results, stably polishing sapphire substrates with a surface roughness RMS < 0.3 nm and a flatness < 5 nm, and the polishing pads have a long service life.