06

Feb

The core competitiveness of the precision manufacturing industry is hidden in every detail of efficient and high-precision machining. Recently, we received an inquiry for CBN inserts from a precision components manufacturer in Thailand. Although the inquiry appeared to involve only two standard insert models, it actually reflected the customer’s stringent requirements for machining high-hardness powder metallurgy materials, and represented another successful practice of empowering overseas precision manufacturing through professional solutions.

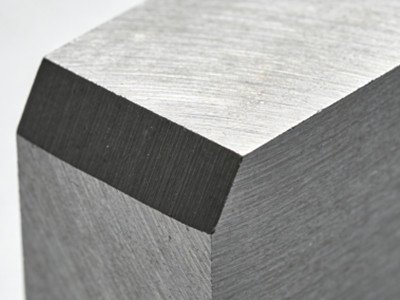

As an experienced precision components manufacturer in Thailand, the customer is currently focusing on finish machining of EN26 sintered powder metallurgy materials. Their core machining requirements and challenges are summarized as follows:

Machining Challenges:

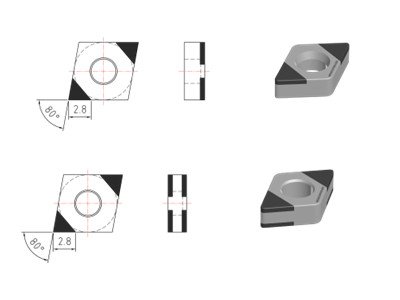

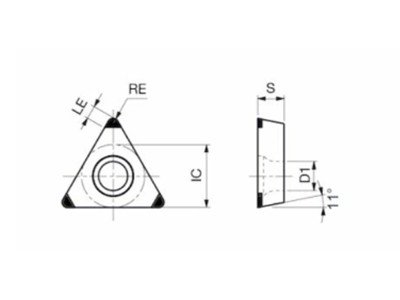

The two CBN insert models specified in the customer’s inquiry are:

3NU-TPGW-110304-HS BN7500 and 2NU-CNGA-120404-LF BN7125.

From the detailed specifications of these models, we accurately identified several key requirements that were not explicitly stated by the customer:

This clearly demonstrates the customer’s extremely strict control over machining accuracy and surface finish.

The combination of these two grades reflects the customer’s core objective: maintaining long tool life and stable machining quality under high-speed cutting conditions, while reducing tool change frequency and overall production costs.

This highlights the customer’s need for both machining flexibility and process stability.

After thoroughly interpreting the customer’s machining challenges, operating conditions, and underlying requirements, we did not simply offer “equivalent substitutes.” Instead, we developed optimized, application-specific solutions designed to exceed performance expectations—improving machining efficiency, extending tool life, and controlling production costs while maintaining superior surface quality.

The recommended solutions are as follows:

Recommended Grade: Customized MBN7520 CBN grade

Reason for Recommendation:

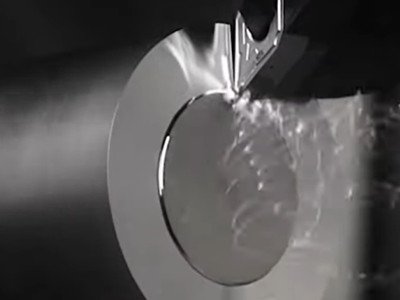

The MBN7520 grade is specifically developed for continuous and lightly interrupted finish machining of hardened steel and sintered powder metallurgy materials in the HRC 55–65 range. Its proprietary micro-edge preparation technology directly addresses the customer’s key issues of micro-chipping and insufficient surface finish. By reinforcing cutting edge strength while effectively preventing micro-chipping, this grade delivers exceptional surface quality that significantly exceeds the customer’s expectations, making it ideal for high-precision finishing operations.

Recommended Grade: MBN7000 general-purpose CBN grade

Reason for Recommendation:

MBN7000 is a highly versatile, high-performance CBN grade featuring a tough substrate structure combined with advanced coating technology. It offers outstanding wear resistance and chipping resistance, making it suitable for both continuous cutting dominated by abrasive wear and more complex interrupted cutting conditions. In customer application testing, the tool life of MBN7000 was approximately 30% longer than that of the originally requested BN7125 grade and comparable market alternatives, significantly reducing tool change frequency, improving machining efficiency, and lowering overall production costs.

This collaboration with the Thai precision components manufacturer was not merely about product supply, but about decoding customer requirements and delivering precise value empowerment. By deeply analyzing the inquiry details and machining challenges, and moving beyond the mindset of simple substitution, we provided customized CBN insert solutions that perfectly matched the customer’s demands for high precision and high stability. At the same time, we successfully achieved a triple upgrade in quality, efficiency, and cost optimization, earning strong recognition from the customer.

Going forward, we will continue to focus on difficult-to-machine applications in the global precision manufacturing industry. Through professional product development, precise application matching, and comprehensive technical support, we are committed to delivering more competitive hard machining solutions for overseas customers—helping precision manufacturers worldwide reduce costs, improve efficiency, and achieve continuous quality upgrades.