05

Feb

In recent months, the price of tungsten carbide (WC) raw materials has been continuously rising, leading to a significant increase in the procurement cost of cemented carbide CNC cutting tools. This sharp cost increase has posed severe challenges to manufacturing enterprises that rely heavily on carbide tools for production, especially in the context of shrinking profit margins in the downstream manufacturing industry. However, many enterprises have not yet realized that in specific machining scenarios, cermet (Cermet) inserts can not only replace cemented carbide inserts but also provide better comprehensive machining performance, helping enterprises achieve cost control and efficiency improvement.

Against the backdrop of the continuous surge in tungsten carbide prices, Moresuperhard Advanced Materials provides a series of high-performance cermet insert products, offering customers a solution with controllable costs, equivalent performance and stable delivery time. For manufacturing enterprises struggling with the high cost of carbide tools, Moresuperhard’s cermet inserts have become a key breakthrough to reduce production costs and enhance core competitiveness, injecting new vitality into the stable development of enterprises.

As the core raw material of cemented carbide tools, tungsten carbide’s price fluctuation directly determines the cost of terminal cutting tools. Since the start of 2026, the domestic tungsten carbide market has entered a “surge mode”. According to the latest industry data, on February 2, 2026, the price of primary tungsten carbide has climbed to 1.42-1.45 million yuan per ton, an increase of 50,000 yuan from the previous day, with a single-day increase of 5%, hitting a record high. Meanwhile, the prices of tungsten powder, cemented carbide blanks and other related core raw materials have also risen sharply, presenting a pattern of “scarce supply and no market at a price” in the whole industrial chain.

The continuous surge in tungsten carbide prices is not a short-term capital speculation, but the result of multiple factors. On the supply side, the total domestic tungsten ore mining control indicators have been continuously tightened, with no new quotas in 2026. Small and medium-sized mines have been shut down one after another due to stricter environmental inspections, and the effective capacity utilization rate of the industry is only 72%. Mining enterprises in major producing areas have jointly raised prices and hoarded goods, making tungsten concentrate in short supply. At the same time, the average grade of domestic tungsten ore has decreased year by year, from 0.42% ten years ago to 0.28%, leading to a sharp increase in mining costs and further restricting the release of production capacity.

On the demand side, the application scenarios of cemented carbide have extended from traditional industry to high-end manufacturing. The demand in emerging tracks such as photovoltaic, military industry and semiconductor has maintained a high growth rate of more than 20%. The stable demand of traditional manufacturing industry combined with the explosive growth of emerging fields has promoted the continuous expansion of the supply-demand gap in the whole industrial chain. The surge in raw material prices has been directly transmitted to the terminal market of cemented carbide CNC cutting tools. Since 2025, manufacturers of cemented carbide rods and cutting tools have raised prices for many times, and the comprehensive impact has become more prominent in 2026. Many enterprises reported that the procurement cost of cutting tools has increased by more than 30% compared with the same period last year, which has seriously squeezed the profit space of enterprises and even affected the normal progress of production plans.

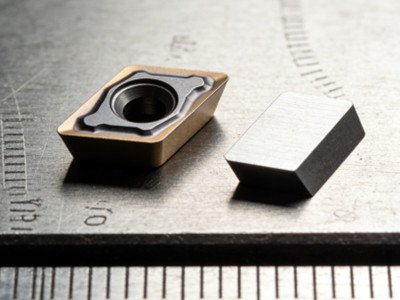

Cermet is a composite material sintered by ceramic phase (such as TiC, TiN, Al2O3, etc.) and metal phase (such as Ni, Co, Mo, etc.) through powder metallurgy technology. It combines the high hardness and wear resistance of ceramics with the toughness and impact resistance of metals. Compared with traditional cemented carbide, cermet materials have the following significant characteristics, which make them an ideal alternative to carbide inserts in specific machining scenarios.

The room temperature hardness of cermet materials can reach HRA 90-93, which is significantly higher than that of conventional cemented carbide (HRA 85-88). Higher hardness means stronger wear resistance. In the machining of common materials such as gray cast iron, ductile iron, carbon steel and alloy steel, the service life of cermet inserts is 1.5-3 times that of carbide inserts, which can greatly reduce the frequency of tool replacement, reduce downtime and improve production efficiency.

Cermet materials have strong chemical stability and anti-adhesion. When machining steel parts, they are not easy to produce built-up edge, which can effectively avoid the damage of built-up edge to the tool and the workpiece surface. This advantage not only ensures the stability of machining quality but also further extends the service life of the tool, reducing the comprehensive machining cost of enterprises.

Due to the low friction coefficient and good thermal conductivity of cermet materials, the cutting process is more stable, and the surface roughness value of the machined workpiece is lower. Compared with carbide inserts, the surface roughness of workpieces machined by cermet inserts can be reduced by 1-2 grades, which can effectively improve the machining accuracy of workpieces, reduce the subsequent grinding, polishing and other processes, and further reduce the comprehensive production cost of enterprises.

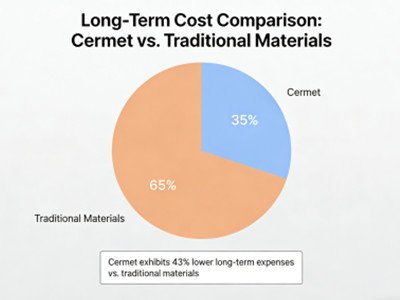

Different from cemented carbide inserts which rely heavily on tungsten carbide, cermet inserts have low tungsten content, and their core raw materials are titanium-based compounds. The price of titanium-based compounds is only 1/5-1/3 of that of tungsten carbide, and their price stability is far superior to that of tungsten carbide. Data show that from 2025 to the first quarter of 2026, the price increase of cermet inserts was only 8%-12%, while the price increase of carbide inserts exceeded 30%. The procurement cost of cermet inserts of the same specification is 25%-40% lower than that of carbide inserts, which can help enterprises save a lot of cost in tool procurement.

| Performance Indicators | Cermet Inserts | Cemented Carbide Inserts |

| Room Temperature Hardness (HRA) | 90-93 | 85-88 |

| Wear Resistance | Excellent, service life is 1.5-3 times that of carbide inserts | Good, but lower than cermet inserts |

| Chemical Stability | Strong, not easy to produce built-up edge when machining steel parts | General, built-up edge is easy to occur in some scenarios |

| Surface Machining Quality (Roughness Grade) | High, roughness can be reduced by 1-2 grades | Good, but higher than cermet inserts |

| Tungsten Content | Low, less affected by tungsten price fluctuation | High, closely related to tungsten price |

| Price Stability (2025-Q1 2026) | Stable, price increase 8%-12% | Volatile, price increase over 30% |

| Procurement Cost (Same Specification) | 25%-40% lower than carbide inserts | Higher, affected by tungsten price surge |

| Impact Resistance | Good, high-toughness products can adapt to medium and low-speed intermittent cutting | Good, suitable for high-speed and heavy-load cutting |

In the current market environment where tungsten carbide prices are soaring and carbide tool costs are high, Moresuperhard Advanced Materials, with its professional R&D strength and rich production experience, provides a series of high-performance cermet insert products to solve the cost pressure of manufacturing enterprises. Moresuperhard’s cermet inserts strictly follow international quality standards, adopt advanced powder metallurgy technology and high-quality raw materials, and undergo strict quality inspection in the production process to ensure that each product can meet the high-standard machining needs of customers.

Moresuperhard’s cermet insert series covers a variety of specifications and models, which can be customized according to the specific machining scenarios and material requirements of customers, and is widely applicable to the machining of auto parts, mechanical parts, molds and other products. Whether it is the machining of gray cast iron, carbon steel, alloy steel or other materials, Mooao’s cermet inserts can provide stable and reliable performance support. At the same time, relying on a complete supply chain system and efficient production capacity, Mooao ensures the stable delivery of products, avoiding the impact of raw material shortage on the production plan of customers.

From the perspective of industry development trends, the high operation of tungsten carbide prices may become the norm. On the one hand, the trend of tightening tungsten ore mining quotas and decreasing grades is irreversible, and the supply constraint will exist for a long time. On the other hand, the demand for cemented carbide in the high-end manufacturing field will continue to grow, and the supply-demand gap is difficult to fill quickly, which will continue to push up the cost of carbide tools. In this context, cermet inserts, as a cost-effective alternative, will usher in explosive growth in market demand.

With the continuous upgrading of cermet material technology, the impact resistance and high-temperature resistance of cermet inserts will be further improved, and the applicable scenarios will be further expanded, which is expected to replace carbide inserts in more high-end machining scenarios. For manufacturing enterprises, actively embracing cermet inserts and other alternative solutions is not only an expedient measure to cope with short-term cost pressure but also a long-term move to enhance core competitiveness.

Choosing Moresuperhard’s high-performance cermet inserts means choosing a cost-effective, stable and efficient machining solution. In the fierce market competition, Moresuperhard Advanced Materials will work together with manufacturing enterprises to seize the development opportunity, realize the goal of “cost reduction, quality improvement and efficiency increase”, and move towards high-quality development together.