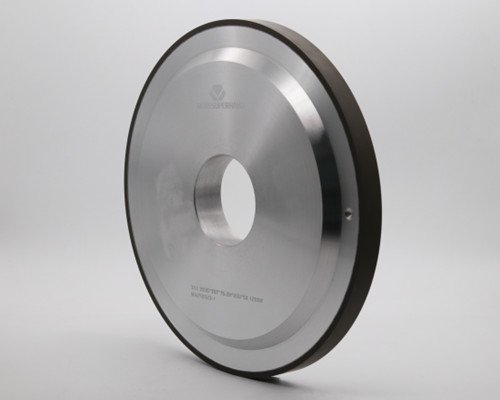

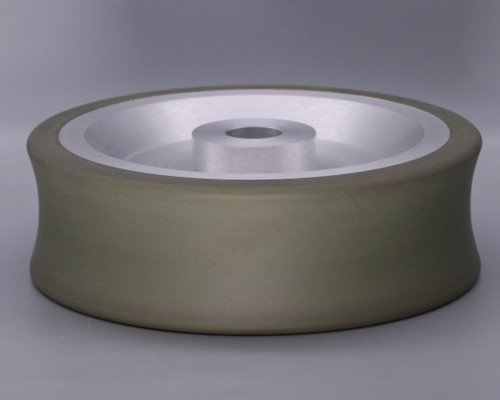

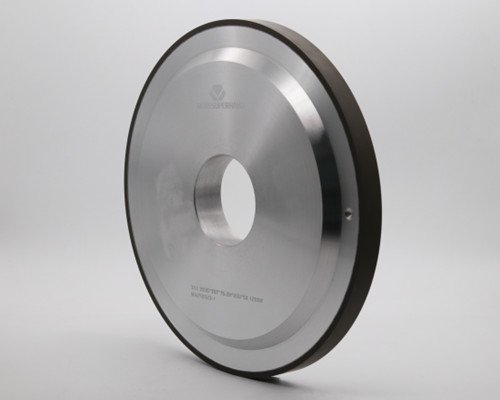

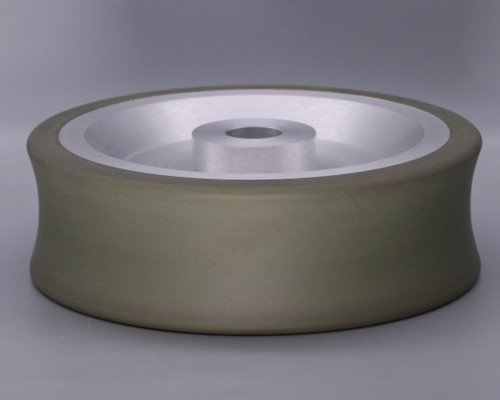

Resin bond CBN grinding wheels are designed for high-efficiency and precision grinding of hardened ferrous materials.

Using cubic boron nitride (CBN) as the abrasive and a specially formulated resin bond system, these wheels provide

excellent self-sharpening performance, low grinding force, and superior surface finish.

Compared with vitrified or metal bond wheels, resin bond CBN wheels offer better elasticity and shock absorption,

effectively reducing workpiece burning, micro-cracks, and edge chipping.

| Abrasive | CBN (Cubic Boron Nitride) |

|---|---|

| Bond Type | Resin Bond |

| Grit Size | B46 – B126 (Custom available) |

| Concentration | C75 / C100 / C125 |

| Hardness | Medium / Hard (Customized) |

| Diameter | Up to Ø700mm |

| Bore | Standard or Customized |

| Coolant | Oil or Water-based Coolant |

Actual grinding parameters should be optimized based on machine condition and application.

Each resin bond CBN grinding wheel is manufactured under strict quality control to ensure consistent abrasive

distribution, stable bonding strength, and reliable grinding performance throughout its service life.

Please provide your material type, hardness, grinding machine, and operation details.

Our engineers will recommend the most suitable resin bond CBN grinding wheel for your application.

Automotive Components Manufacturing

The customer experienced frequent grinding burn and unstable surface roughness when using conventional alumina

grinding wheels. Wheel wear was high, requiring frequent dressing, which reduced productivity and increased cost.

We recommended a resin bond CBN grinding wheel with optimized grit size and concentration,

designed to balance cutting efficiency and surface finish.