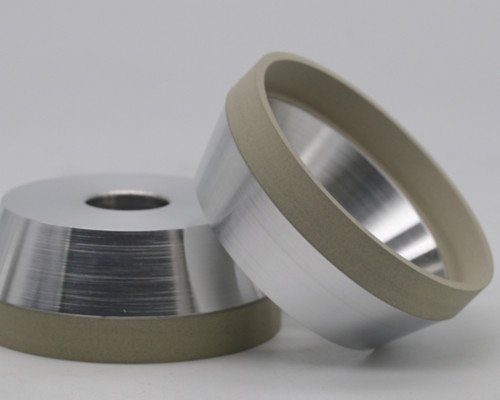

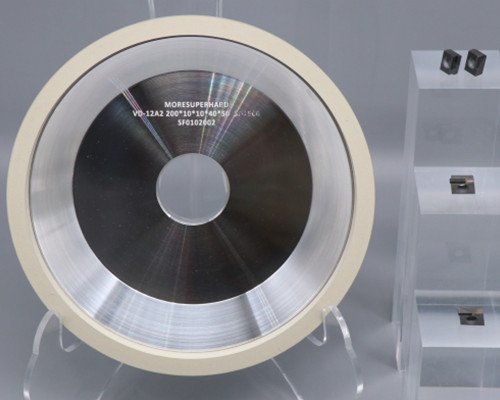

Diamond vitrified grinding wheels are designed for precision sharpening of cutting tools in the form of inserts and cutting tools made of polycrystalline PCD, polycrystalline PCBN, natural diamonds and a new type of engineering structural ceramics.

The vitrified diamond wheel has uniform micro porosity allow wheel to cut sharp and aggresive prevent the clogging the wheel’s surface.

Application of vitrified diamond grinding wheel

Moresuperhard produce a wide range of diamond wheel in vitrified (ceramic ) bond for precision grinding, finishing, sharpening, peripheral grinding of PCD, PCBN, MCD and natural diamond.

– For PCD, PCBN super-hard cutting tools grinding

– For PCBN cutting tools grinding

– For polycrystalline diamond compacts ( PDC ) grinding

– For tungsten carbide cutting tool grinding

– For ceramic tools grinding

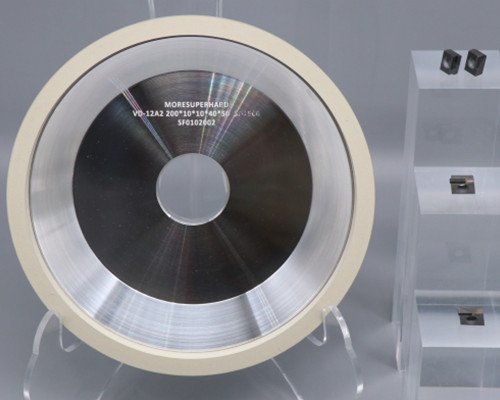

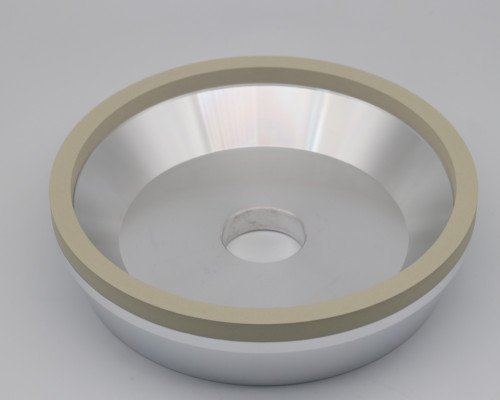

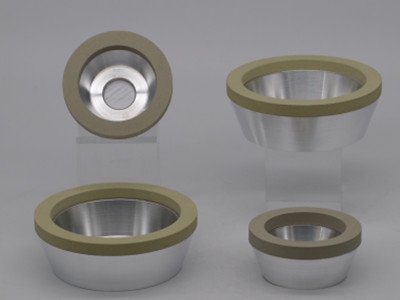

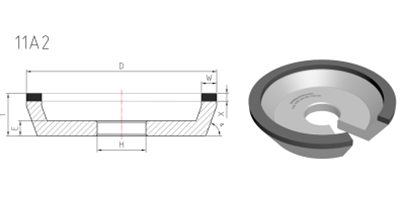

Specifications Of Vitrified (ceramic) Diamond Wheel

| Type | D(mm) | T(mm) | H(mm) | W(mm) | X(mm) |

| 11A2 | 100 | 40 | 32 40 | 3 5 10 20 | 10 |

| 125 | 40 | 32 40 | 3 5 10 | 10 | |

| 150 | 40 | 32 40 | 3 5 10 15 20 | 10 | |

| Grit: 325/400 W40(500#) W28(600#) W20(800#) W10(1500#) W7(2000) W5(3000#) W3.5(4000#) 6000# | |||||

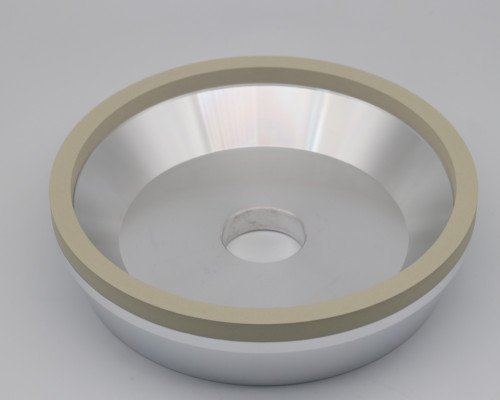

Advantages Of Vitrified Diamond Grinding Wheel For Pcd

– Precision control of geometric tolerance

– Extremely long lifetime through high adhesion strength of the diamond grain

– Good self-sharpening

– Superior insert edge quality

– High cutting ability with profile retention

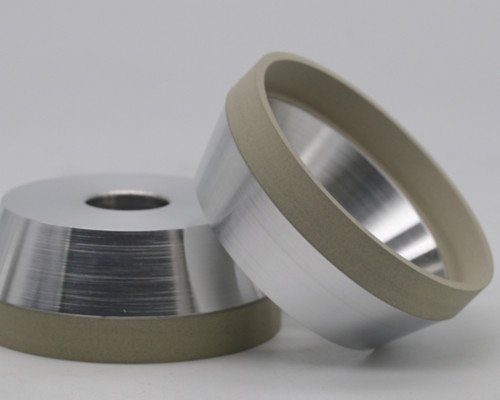

Grain Size Selection Of Vitrified Diamond Wheel For Pcd

| Grain Size | Machining Type | Application |

| W40(400-500#,D35)W28(600-700#,D20) | Rough | Regrinding a blade edge profile and sharpening of much worn inserts |

| W20(800-1000#,D20) | Universal | Standard grain size also can get a high sharpening efficiency, good quality surfaces |

| W10 (1500#, D15A) W7(2000#,D15B) | Finish | Finishing grinding – getting a very good quality of machined surfaces |

| W5 (3000#, D7) W3.5 (4000#,D3) | Super Finish | Super finish grinding – getting a brilliant quality of machined surfaces |