29

Oct

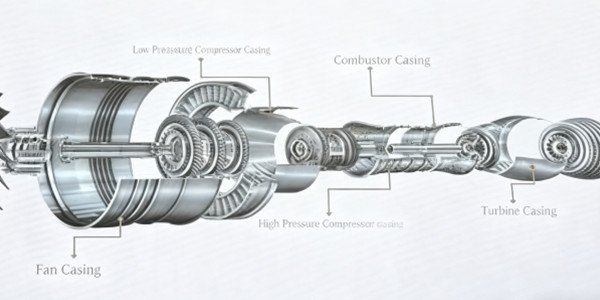

The engine casing is one of the most critical structural components of an aero-engine. It serves as the main load-bearing and assembly part, with complex geometry, large dimensions, and thin walls.

Common materials such as titanium alloys, nickel-based superalloys, stainless steels, and aluminum alloys present the following machining challenges:

| Process | Machining Area | Key Features | Tooling Solutions |

|---|---|---|---|

| Rough Turning – Inner Diameter | Large internal cavities | Heavy stock removal, difficult chip evacuation | CBN or coated carbide turning tools with strong chip breakers and positive rake angles to reduce cutting forces. Ideal for high-temperature alloys. |

| Finish Turning – Inner Grooves | Sealing and positioning grooves | High dimensional and surface accuracy | PCBN or diamond-coated tools for micro-tolerance finishing and mirror-like surface quality. |

| Rough Milling – Ring Band | Reinforcing ribs | Interrupted cuts and vibration issues | Solid carbide or ceramic end mills with variable pitch design for stable cutting of Inconel 718 and similar alloys. |

| Rough Milling – Bosses | Reinforcement structures | Localized heavy cuts, high heat generation | Coated carbide end mills or indexable cutters with strengthened cutting edges for high wear resistance. |

| Rough Milling and Drilling – Flanges | Outer ribs and bolt holes | Interrupted cutting, precise hole location | PCD/CBN combination tools for milling, and carbide drills with internal cooling for efficient chip evacuation and hole quality. |

CBN Turning Tools

Designed for rough and finish turning of nickel-based or cobalt-based superalloys.

High thermal resistance and long tool life.

PCD Tools

Ideal for machining aluminum or titanium alloy casings.

Excellent for high-precision hole machining and fine surface finishing.

Ceramic Inserts (SiAlON / Al₂O₃-based)

Suitable for rough milling of superalloys.

High cutting speed capability and superior thermal shock resistance.

Solid Carbide End Mills and Drills

Internal cooling design for deep cavity and hole machining.

TiAlN / TiSiN coatings provide outstanding wear and heat resistance.

Moresuperhard provides a complete tooling solution for aero-engine casing machining, covering turning, milling, and drilling operations.

By combining PCD/CBN superhard cutting tools with advanced coating technology, we help customers achieve high precision, high efficiency, and high reliability in aerospace component manufacturing.