09

Oct

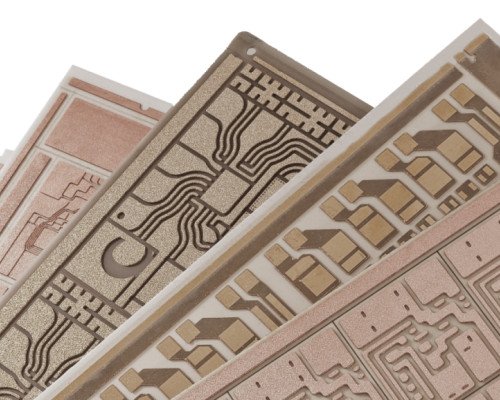

Ceramic substrates have the advantages of excellent electrical insulation properties, high thermal conductivity, high reliability, and small thermal expansion coefficient. They have become the basic material for high-power electronic structure technology and interconnection technology.

Due to the hard and brittle nature of ceramic materials, it is very difficult to process through holes and scribe. Traditional mechanical processing methods are time-consuming and labor-intensive, and there is stress during the processing, which can easily damage the substrate. With the increasing requirements for the processing accuracy and efficiency of ceramic substrates, traditional mechanical processing methods can no longer meet the needs. Ceramic substrates are usually cut by laser cutting or blade cutting.

Laser processing technology has the advantages of non-contact, flexibility, high efficiency, easy digital control, and high precision, making it one of the most ideal means of ceramic processing today. Laser scribing is also called scratch cutting or controlled fracture cutting. Its mechanism is that the laser beam is focused on the surface of the ceramic substrate through the light guide system, an exothermic reaction occurs to generate high temperature, ablating, melting and vaporizing the ceramic scribing area, forming interconnected blind holes (grooves) on the ceramic surface. If stress is applied along the scribing area, due to the stress concentration, the material can easily break accurately along the scribing line to complete the slicing.

Ceramic laser scribing has to overcome two technical difficulties, namely “spatter” and non-directional fracture.

① “Spatter” accumulation will make the scribing surface rough;

② Non-directional fracture is the irregular fracture or explosion after being subjected to a small external force or high temperature baking after scribing;

Both phenomena will bring difficulties and losses to the manufacture of thick film circuits. There are three solutions:

① Add protective gas

② At the same frequency, try to choose a smaller laser pulse width for scribing. The smaller the pulse width, the greater the peak power, the greater the vaporization ratio of the ceramic, the shorter the heating time, and the smaller the heat affected zone

③ Try to make the light path unobstructed, use a beam expander to compress the divergence angle of the light beam, reduce the spot size at the focal plane of the focusing lens, and try to make the laser beam irradiate vertically to the ceramic processing surface to reduce aberrations and make the laser irradiation energy more uniform.

Laser scribing has the advantages of fine scribing, fast scribing speed, smooth cross section, and no damage to the substrate.

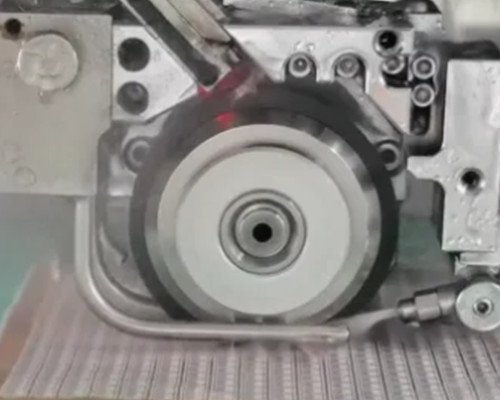

Mechanical scribing is the use of a blade to physically cut a ceramic substrate. The scribing blade is generally made of synthetic resin, copper, tin, nickel, etc. as a binder combined with artificial diamond. During cutting, the spindle drives the blade to rotate at high speed to obtain high rigidity, thereby removing the material to achieve cutting.

The blade has a certain thickness, requiring a larger scribing line width. The minimum cutting line width that a diamond scribing blade can achieve is 25~35um. Different tools need to be replaced to cut substrates of different materials and thicknesses. During the rotating grinding wheel scribing process, deionized water is required to cool the blade and remove the debris generated after cutting.

• Low cutting cost, small equipment investment, low operation and maintenance costs.

• Cold cutting, no heat-affected zone is produced on the material, and the original performance and characteristics of the material are maintained.

• No requirements for material properties and thickness, any material can be cut, and the cutting thickness can reach 300mm.

• No harmful substances and pollution are produced, safe and environmentally friendly.

Moresuperhard provide quality diamond dicing blades for ceramic substrates including resin diamond dicing blades and electroplated diamond dicing blades.If you need ,please contact us freely.