04

Sep

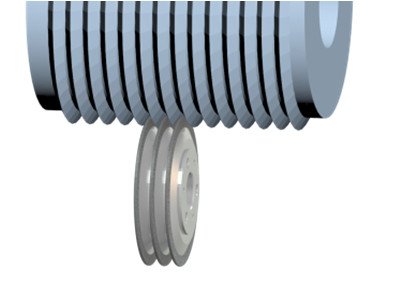

Metal Sintered Diamond Roller

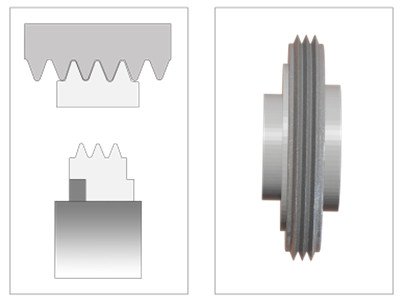

Electroplated Diamond Rotary Dresser

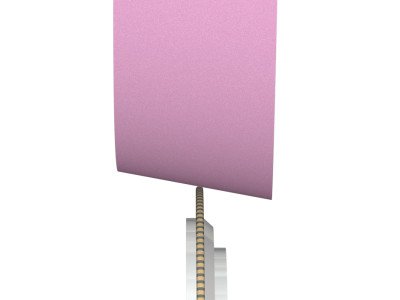

In short, the harder the workpiece material, the shorter the roller lifespan.

The service life of diamond dressing rollers depends on multiple factors: manufacturing quality, workpiece material, operating parameters, machine accuracy, and maintenance practices. By selecting the right roller type and bond, optimizing grinding parameters, ensuring proper cooling, and following correct operating procedures, manufacturers can significantly extend roller life and achieve high efficiency, cost savings, and consistent quality.

MoreSuperHard provides customized diamond dressing roller solutions tailored to customer needs, helping improve dressing efficiency and reduce overall costs.