09

Mar

Applications of single crystal diamond cutting tools

Single crystal diamond cutting tools have the advantages of extremely high hardness and wear resistance, high elastic modulus, high thermal conductivity, low expansion coefficient, and low affinity with non-ferrous metal elements. It is mostly used for high-precision turning of non-metallic brittle and hard materials, graphite materials, high wear-resistant materials, composite materials, high-silicon aluminum alloys and tough non-ferrous metal materials.

Difficulties in grinding single crystal diamond tools

Single crystal diamond tools have obvious advantages, but they often encounter some problems when producing and processing single crystal tools, such as high cost, low efficiency, short life, and insufficient precision.

Today,Moresuperhard has compiled four problems that novices in single crystal diamond tool grinding will encounter and share them with you.

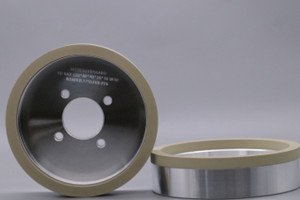

1.How should single crystal diamond tools be sharpened? What grinding wheel to use?

Use diamond grinding wheels to perform rough grinding, semi-fine grinding, and fine grinding on single crystal diamond tools. If there are polishing requirements, a cast iron disc may be used for ultra-fine grinding. The selection of diamond grinding wheels needs to be based on specific grinding requirements and grinding machine conditions. Generally speaking, metal diamond grinding wheels or ceramic diamond grinding wheels are used to grind single crystal diamond tools.

2. Can my current grinder be used to grind single crystal diamond tools?

Generally speaking, Moresuperhard can design the grinding wheel model and size based on the customer’s existing equipment, but the specific grinding effect needs to refer to the precision control of the customer’s equipment.

3.Can ceramic diamond grinding wheels be used to grind single crystal diamond tools, and what is the grinding effect?

Of course, ceramic bonded diamond grinding wheels can be used to grind single crystals. Currently, we have actual case parameters showing that using ceramic grinding wheels to grind single crystal tools can control chipping below 2 μm, which can meet the needs of 3C and jewelry industry applications.

4.What grit size grinding wheel is suitable for fine grinding of single crystal diamond tools?

The selection of particle size should be based on the accuracy requirements of the customer’s grinding tools. At present, the smallest particle size of metal diamond grinding wheels can reach 15,000#, and the smallest particle size of ceramic diamond grinding wheels can reach 10,000#.

Notes:Coolant must be used when grinding single crystal diamond tools with ceramic diamond grinding wheels. Metal diamond grinding wheels can be used to grind single crystal diamond tools dry, but dressing metal diamond grinding wheels requires electrical machining or the use of a special grinding wheel dressing machine.

If you need any help about grinding single crystal diamond tools,please contact us freely.