11

Dec

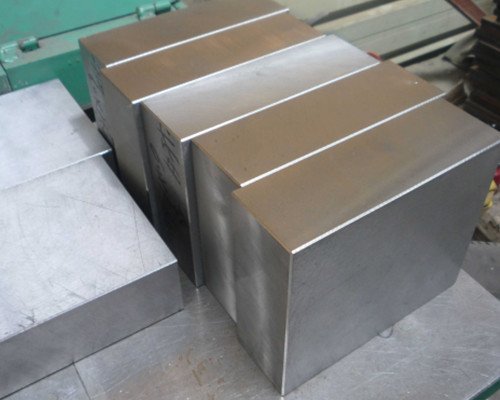

Mold steel is widely used in mold manufacturing due to its high hardness, high strength and wear resistance. However, these characteristics also make it difficult to process, especially in scenarios with high precision requirements, which puts higher requirements on the performance of processing tools. Vitrified bond CBN (cubic boron nitride) grinding wheels have been widely used in mold steel processing due to their superior grinding performance. The following is a real case showing its application effect in mold steel mold processing.

A mold manufacturing company needs to process a set of hot-working mold steel (H13 material) dies for aluminum alloy die-casting production. The core component requirements of the die are:

Workpiece hardness: HRC 58-62;

Surface roughness: Ra ≤ 0.2μm;

Dimensional accuracy: ±0.01mm;

Processing efficiency: meet the needs of mass production.

Due to the high hardness and toughness of H13 mould steel, traditional grinding wheels are difficult to meet the needs of high-efficiency and high-precision processing, so it is decided to use ceramic bond CBN grinding wheels for grinding.

Grinding wheel type: ceramic bond CBN grinding wheel;

Grit selection: 180# is used in the rough grinding stage and 400# is used in the fine grinding stage;

Grinding wheel shape: flat grinding wheel (1A1 type), adapted to the mold structure characteristics;

Binder characteristics: ceramic bond has good porosity and grinding self-sharpening, suitable for the processing of high-hardness materials.

Use high-precision CNC grinders and the following parameters for grinding:

Spindle speed: 1800-2400 RPM;

Grinding depth: 0.03mm per feed in the rough grinding stage, and controlled within 0.005mm in the fine grinding stage;

Cutting fluid: water-based coolant to ensure temperature control in the processing area and reduce thermal stress.

Rough grinding stage: quickly remove material to form the basic shape of the mold;

Fine grinding stage: further process the mold surface to reach the designed size;

Polishing grinding: use high-grain CBN grinding wheels for surface polishing to improve the surface quality of the mold.

Processing accuracy: the mold size error after processing is controlled within ±0.008mm, meeting the design requirements.

surface quality:the surface roughness of the mold reaches Ra 0.15μm, which is better than the expected target and greatly improves the service life and production efficiency of the mold.

Processing efficiency:after using ceramic CBN grinding wheels, the processing efficiency increased by about 30%, and the processing time of a single mold was shortened from 12 hours to 8 hours.

Grinding wheel durability:the ceramic bonded CBN grinding wheel performs well when processing H13 mold steel. It can continuously complete the processing of 50 molds after a single dressing, and the tool life is significantly improved.

1.High hardness and high toughness of mold steel

Traditional grinding wheels are prone to wear, resulting in low processing efficiency and difficulty in ensuring dimensional accuracy.

Countermeasures: Ceramic CBN grinding wheels have extremely high hardness and wear resistance, and are suitable for efficient processing of high-hardness steel.

2. Thermal stress causes mold deformation

Grinding heat can easily cause thermal cracks or deformation on the mold surface, affecting the processing quality.

Countermeasures: Use water-based coolant and optimize the porosity of the grinding wheel to enhance the cooling effect and reduce the temperature of the processing area.

3.Balancing surface quality and efficiency

Ensuring production efficiency while pursuing high surface finish is a challenge.

Countermeasures: By rationally selecting the grinding wheel particle size and processing parameters, flexibly switch between rough grinding and fine grinding, taking both efficiency and quality into consideration.

This case demonstrates the superior performance of ceramic CBN grinding wheels in H13 mold steel processing:

High precision:processing dimensions and surface quality meet design requirements;

High efficiency:significantly shorten processing time and improve production rhythm;

Long life:The grinding wheel has strong durability and reduces production costs;

High stability:The grinding process is stable without cracks or dimensional loss of control.

With its excellent self-sharpening, wear resistance and thermal stability, ceramic bonded CBN grinding wheels provide mold manufacturing companies with efficient and reliable processing tools, and are the best choice for processing high-hardness mold steel. In the future, with the continuous advancement of processing technology, CBN grinding wheels will play a greater role in more difficult processing scenarios.