17

Jun

Niobium-Titanium alloy (NbTi) is one of the most widely used low-temperature superconducting materials in the world. Known for its high current-carrying capacity and excellent performance under strong magnetic fields, NbTi is commonly applied in MRI magnets, particle accelerators, and other critical fields requiring superconductivity. However, the grinding and machining of NbTi superconductors pose significant challenges due to their physical and thermal characteristics.

NbTi is a binary alloy composed of niobium (Nb) and titanium (Ti). It becomes superconducting below its critical temperature (Tc) of around 9.2 Kelvin. With the ability to carry high currents and withstand magnetic fields up to 10 Tesla, NbTi is widely used for superconducting wires and tapes. These materials are often embedded in coils and cryogenic environments, where surface quality and mechanical integrity are critical for performance and reliability.

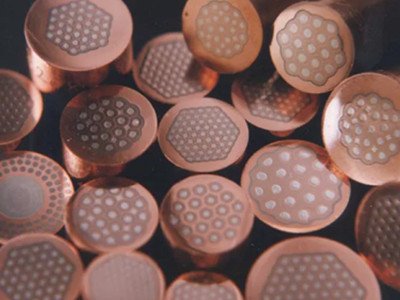

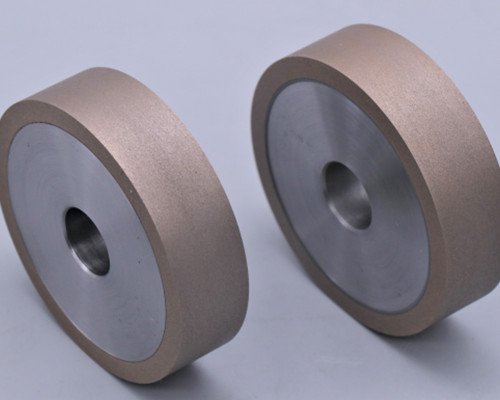

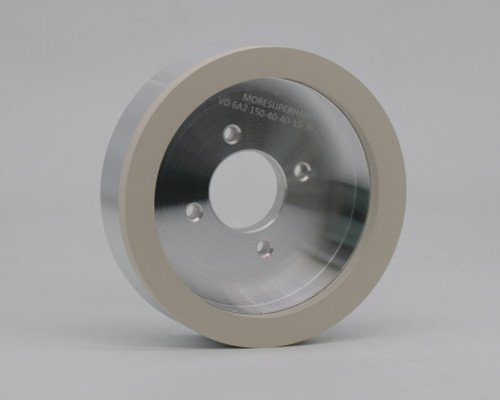

Conventional abrasives like aluminum oxide or silicon carbide are not suitable for efficient NbTi processing due to rapid wear and clogging. Instead, diamond grinding wheels are the preferred solution, providing higher durability and better surface finish. The choice of bond type depends on the stage of grinding:

| Workpiece Form | Recommended Wheel Type | Grit Size | Bond Type | Application |

|---|---|---|---|---|

| NbTi Wire / Bar | Resin Diamond Wheel | #800–#1000 | Resin | Finish grinding |

| NbTi Strip / Foil | Vitrified Diamond Wheel | #320–#800 | Vitrified | Semi-finishing, edge trimming |

| NbTi Pipe / Rod | Metal Bond Diamond Wheel | #150–#400 | Metal | Rough grinding, shaping |

For optimal results, grinding NbTi requires precise control of process parameters and the use of effective cooling systems:

Grinding NbTi superconducting alloys demands a deep understanding of both the material properties and abrasive technology. By selecting the correct diamond grinding wheels and fine-tuning the process parameters, manufacturers can achieve excellent surface quality, ensure product integrity, and extend tool life. For applications requiring precision and low-loss processing of NbTi wires, tapes, or components, choosing the right grinding solution is essential for success in high-tech industries.

We specialize in manufacturing custom diamond grinding wheels for superalloys, superconductors, and advanced materials. Contact us to discuss your project or request a sample wheel for evaluation.