26

Feb

The grinding of diamond tools has its own process characteristics. The more prominent feature is the high hardness of the material, which causes the grinding wheel to lose too fast and the size is unstable during the grinding process. Most of the diamond tools are turning tools or blades, and the position of the grinding part relative to the machine tool is uncertain (such as the change of the thickness of the blade), which causes the change of the grinding point. The high grinding resistance makes the process system composed of grinding wheel, tool, fixture and machine tool produce relatively large elastic deformation, resulting in a relatively large “knife yielding” phenomenon.

These three features are the three “land rovers” that realize automatic grinding, which directly affect the dimensional accuracy of the tool after die cutting. If it is not solved properly, it will inevitably lead to poor consistency of grinding dimensional accuracy and roughness, and low grinding efficiency, which is not suitable for mass production.

PCD tools show excellent cutting performance in high-speed cutting of non-ferrous metals and their alloys and non-metallic materials, so they have been widely used in automotive, aviation, aerospace, building materials and other industrial fields. However, the high hardness and high wear resistance of PCD make it difficult to sharpen the tool, which is mainly reflected in the low material removal rate, large grinding wheel loss, low sharpening efficiency and serrated edge. The sharpening manufacturability of PCD tools has become one of the obstacles to its popularization and application.

When rough grinding diamond PCD tools, what are the main factors affecting the grinding efficiency?

1. Grinding direction

The grinding direction should be the easy grinding direction of the diamond crystal. Deviation from the easy grinding direction of the mirror surface to be ground will greatly reduce the grinding efficiency. If it encounters a difficult grinding direction, slippage, vibration, noise and grinding will occur. When you find the easy grinding direction, you can feel smooth and normal, and sometimes there are small sparks of light yellow or light blue. At this time, the grinding process will become very smooth, and the grinding efficiency will be relatively improved.

2. Grinding speed

In order to obtain more grinding amount, it is necessary to increase the line grinding speed, but due to the limitation of objective conditions, the increase of the line speed is limited, so to increase the line speed, the diameter of the grinding wheel should be increased, or the grinding wheel should be increased. speed. Increasing the diameter of the grinding wheel is a shortcut to increase the linear speed, but increasing the diameter of the grinding wheel without limit will increase the volume and weight of the grinding machine, which is not conducive to the loading and unloading of the grinding wheel. In addition, when starting and stopping, the resistance distance of the grinding wheel is too large. Therefore, choosing the right wheel size is also crucial.

3. Loads on the diamond

Increase the load when grinding diamond to obtain greater grinding force, thereby improving the grinding efficiency. Under normal circumstances, the load should not be too large, otherwise the grinding force will be too large, resulting in a large grinding heat, which will affect the surface quality of the diamond, and sometimes cause cracks, damage or oxidation of the diamond.

4. Diamond powder particle size

The use of coarse-grained diamond micropowder can improve the grinding efficiency. However, to increase the roughness of the ground diamond surface, a coarser-grained diamond micropowder can be used at the beginning. In the later stage of rough grinding, a smaller grain size is required. The diamond powder can get better surface quality by doing so. Precision machining has high requirements for tools, because diamond has extremely high hardness and is widely used in precision machining tool design.

The main sharpening processes of PCD tools include EDM sharpening, diamond grinding wheel mechanical sharpening, Laser sharpening, etc

1. Discharge sharpening and diamond grinding wheel mechanical sharpening are relatively mature in technology. Discharge sharpening (EDG) is an electrical discharge machining technology (EDM) (especially wire EDM and electrical discharge grinding) that has been widely used in cutting tools. In manufacturing, the electrical discharge machining technique used to sharpen PCD tools is called electrical discharge sharpening (EDG).

EDM semi-finishing and finishing PCD tools is a high-efficiency machining method. However, the high temperature of the discharge during processing will cause certain damage to the surface and interior of the PCD. Compared with high-precision grinding, the quality of the cutting edge is not very good.

Summary: EDM electrical machining will oxidize the surface PCD particles, change the properties of PCD, and affect tool life. The tool chip breaker cannot be machined, the cutting edge of the tool has a large degree of chipping, which affects the surface effect of the machine and produces environmentally harmful waste.

2. Diamond grinding wheel mechanical grinding is currently the most widely used PCD tool grinding method. Compared with discharge grinding, its grinding efficiency is lower (the removal rate is about 1.5mm3/min), and the processing cost is higher (wear and tear). The ratio is about 0.02min3/min3), but good cutting edge quality and complete and smooth front and flank surfaces can be obtained. When the grinding wheel is in contact with the PCD, the grinding force suddenly increases, and the severe mechanical impact causes cracks and even fragments on the surface of the PCD. During the stable grinding period, the abrasive particles of the grinding wheel are squeezed and rubbed on the surface of the PCD. When the pressure reaches a certain level, cracks will form on the surface of the PCD. when the friction temperature reaches a certain level, the PCD will undergo graphitization and other chemical reactions. Through experiments, it is found that when grinding with a grooved diamond grinding wheel, due to the discontinuous grinding force and the periodic cooling effect of the coolant, it is conducive to crack propagation, so that the grinding efficiency of the grooved grinding wheel is higher than that of the non-grooved grinding wheel. 1 to 2 times.

When grinding PCD with diamond grinding wheel, the requirements for sharpening equipment are much higher than that of general tool grinders. Due to the high hardness of diamond, the grinding force is much higher than that of grinding cemented carbide, and the grinding force is very large, which easily loosens PCD particles and affects the service life of the tool.

PCD materials are mainly divided into three categories according to particle size: coarse particle size (20-50μm), medium particle size (about 10μm) and fine particle size (-5μm). , The quality is poor, but the wear resistance is the strongest; fine-grained grinding is easier, and the quality of the cutting edge after grinding is better. However, complex contour tools cannot be machined, tool chip breakers cannot be machined, and processing efficiency is low.

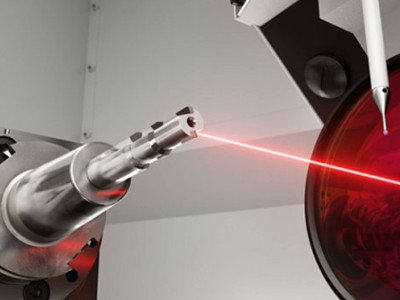

3. PCD tool cold laser machining realizes the edge manufacturing of the tool to be machined by removing material by the laser beam, and makes the laser beam perform outer contour removal by flexibly moving the tool.

Cold laser processing can process the rake angle and the rear angle of the cutting edge at the same time, with high processing efficiency and flexible control of various parameters of the cutting edge.

Unlimited machining tool profile, PCD edge chipping degree < 0.005mm, chip breaker can be machined, high dimensional accuracy of the tool, no thermal damage, five-axis equipment, one-time machining of the cutting edge, high processing efficiency, and environmental friendliness.

The characteristics of PCD materials determine that the requirements for PCD tool sharpening machines are different from those of ordinary tool grinding machines, that is, the grinding wheel spindle and the machine tool as a whole are required to have high rigidity and stability, so as to maintain the constant pressure of the grinding wheel on the PCD material during sharpening. The grinding wheel frame can be oscillated laterally to ensure that the end face of the grinding wheel wears evenly; the swing frequency and swing amplitude of the grinding wheel frame are adjustable. The machine tool should be equipped with an optical projection device and a high-precision rotary table. Special diamond grinding wheels should be used.

Vitrified diamond cup wheels are used for grinding and regrinding pcd, pcbn, mcd, carbide and ceramic cutting tools. MoreSuperHard devotes to offer an efficiency and economic solution in PCD and CBN cutting tools grinding. We can supply quality PCD grinding wheel at very long life as well as fast cutting. We only choose the very strong synthetic diamond as the raw materials, make sure not only the particle shape is round enough but also be with some sharp points, which can make sure we won’t lose the efficiency while we still want enough life from the wheels. So it will help you get fast, stable, much more PCD tools in unit time.