15

Nov

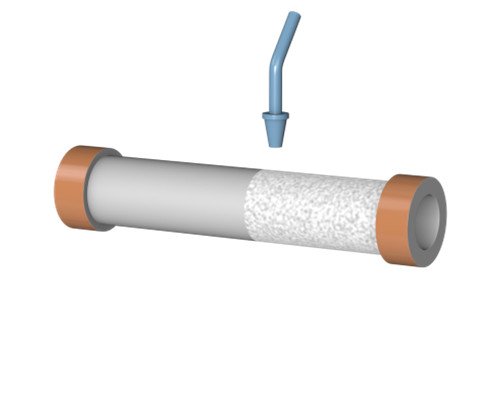

1.Nickel-based alloy thermal spray materials. Itis based on Ni-Cr solid solution and distributed with hard points such as chromium carbide and chromium boride. Mainly composed of nickel, chromium, boron, silicon and other elements.

2.Cobalt-based alloy spraying material is also called Stellite cemented carbide. This alloy is based on a solution of tungsten and chromium, with hard points such as chromium carbide, tungsten carbide, and boride distributed.

3.Iron-based alloy spray materials. Mainly composed of iron, chromium, boron, silicon and other elements. This alloy is distributed with strip-shaped borides and network-shaped carbides on the austenite matrix. In addition, there are copper-based alloys and composite alloys.

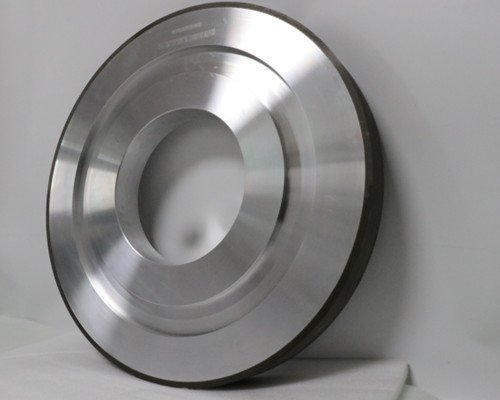

(1) Low durability of grinding wheel

When grinding high-hardness plasma sprayed layers, the grinding wheel tends to become blunt quickly and lose its cutting ability.

(2) Vibration is easy to generate

Due to the uneven surface and the uneven hardness of the sprayed layer, the dispersed distribution of internal hard particles, and the presence of many tiny pores, the grinding force during grinding will fluctuate, causing vibration and impact during the grinding process, which is very unfavorable for the processing quality (such as dimensional accuracy and surface roughness) and the life of the grinding wheel.

(3) High grinding temperature

The thermal sprayed coated, especially some high-hardness sprayed coated with HRC>50, has a large number of dispersed hard particles, which greatly improves their wear resistance. Therefore, a large grinding force and grinding heat are generated during processing. In addition, the thermal conductivity of the sprayed coated is low, and the grinding heat is not easy to be transmitted from the workpiece material, causing the grinding temperature to rise rapidly. Too high grinding temperature can easily burn the machined surface and cause cracks on the machined surface, so effective cooling methods should be used.

The green silicon carbide, cubic boron nitride and diamond abrasives suitable for grinding high-hardness plasma spray coatings.

The harness of soft grades G and H should be selected.

The selection of particle size is mainly based on the requirements of the roughness surface. Generally, the most commonly used grit is 50/60, 80/100, 100/120 . If need better roughness and a larger particle size can be selected.

I