24

Jul

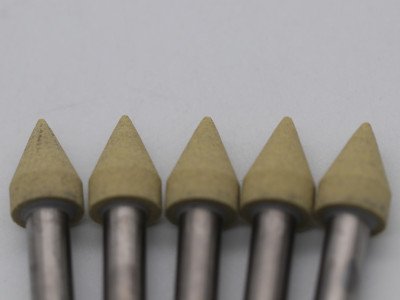

When machining graphite, selecting the appropriate diamond grinding wheel binder is crucial due to graphite’s brittleness, wear resistance, and specific machining requirements (such as efficiency and precision). The following binder types are commonly suitable for graphite processing:

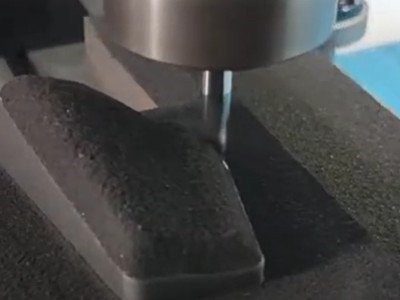

Optimizing machining parameters is essential for ensuring the quality (such as surface roughness and dimensional accuracy), efficiency, and tool life. The key parameters to adjust include:

When selecting a grinding wheel, consider the specific customer’s operational environment. If the customer’s equipment is compatible with dressing tools, then a wide range of bond types can be used. Otherwise, wheels with good self-sharpening properties, such as electroplated or ceramic bond wheels, should be preferred.

Additionally, it’s important to determine the following details for precise wheel selection:

With the proper selection of grinding wheels and adjustment of parameters, the efficiency, precision, and tool life in graphite machining can be optimized.