09

May

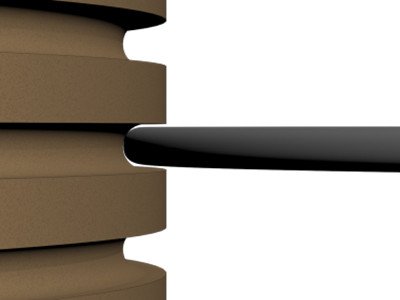

In semiconductor wafer manufacturing, edge chamfering is a critical yet often underestimated process.Though small in scope, it directly impacts wafer integrity, mechanical strength, and downstream process yield.The tool that makes this possible is the chamfering wheel—and more specifically, the metal-bond diamond chamfering wheel, which plays an irreplaceable role under high-precision, high-stability demands.

During dicing, handling, and packaging, wafer edges are vulnerable to stress concentration, often leading to microcracks or even breakage. Chamfering removes sharp edges, forming a controlled arc or bevel that helps relieve stress,minimize chipping, and enhance wafer strength.

As manufacturing environments become increasingly stringent, chamfer quality is now critical to ensuring high yield.

And that quality starts with a chamfering wheel that delivers reliable performance and dimensional stability.

We specialize in metal-bond diamond chamfering wheels, designed specifically for high-performance semiconductor materials. These tools offer the following core benefits:

Chamfering isn’t just about edge removal—it’s about controlled transitions.Achieving smooth, consistent, and dimensionally accurate bevels requires a tool engineered for micrometer-level reliability.Our metal-bond diamond chamfering wheels are built to meet these demands—offering stable, repeatable performance and consistently high-quality edge profiles.

In semiconductor manufacturing, no detail is too small to matter. A high-quality chamfering wheel is more than just a tool—it’s a

guardian of wafer integrity.

We focus solely on providing proven, reliable metal-bond diamond chamfering wheels,

helping our customers maintain stable production and uncompromised quality.

📩 Interested in technical specs or sizing details?

Feel free to contact us— we’re happy to support your wafer processing needs with dependable, high-performance tools.