02

Sep

In the manufacturing industry, precision machining has always been the threshold to high-end manufacturing. For example, the oil holes of engine fuel injection pumps, the inner cavity of hydraulic valve bodies, and the bearing holes of precision gears often require accuracy within 1 micron—equivalent to one-seventieth of the thickness of a human hair!

In the past, such high-precision machining relied primarily on honing, a process that was inefficient and costly. However, in 2022, Rijin Intelligent Equipment, a company in Taizhou, China, introduced a new machining technology: honing, which makes micron-level machining fast and accurate.

So, what exactly is honing? Why has it become a new favorite in precision manufacturing? Let’s find out!

Simply put, honing, also known as single-stroke honing, is a “two-in-one” ultra-precision machining technology that combines the sizing characteristics of “reaming” with the finishing capabilities of “honing”.

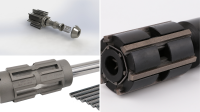

✔Core Tools:The key is a special knife—a honing reamer. It looks a bit like an ordinary carbide reamer, but its “inner” is very different. Its outer surface is coated with a layer of diamond abrasive, and these tiny “diamond teeth” grind the material.

✔Working Principle: A honing reamer, mounted on a dedicated multi-axis machine tool, achieves both precise hole dimensional control and high-quality finish with a single feed stroke (single stroke). A clever taper sleeve on the tool shank allows for fine-tuning of the tool’s outer diameter, similar to screwing a screw, ensuring precise machining.

✔Processing Objects: Specialized in tackling tough materials like hardened steel and even ceramics, which are difficult for ordinary knives to cut, it can easily handle them.

The honing process didn’t emerge out of thin air; it stemmed from the manufacturing industry’s urgent need for high-efficiency, high-precision machining. In 2022, Taizhou Rijin Intelligent Equipment Co., Ltd. in China pioneered this technology and launched honing. This technology combines the sizing capabilities of a reamer with the surface finishing capabilities of honing, and incorporates diamond coating to enhance efficiency.

Today, honing has become an important choice for high-precision internal hole processing, especially in the fields of automobiles, aerospace, precision instruments, etc.

As long as micron-level precision and ultra-high finish are required for internal hole processing, the honing process can often show its strength:

✔Automobile industry: engine fuel injection pumps, connecting rods, piston holes;

✔Hydraulic system: valve body, valve sleeve, precision oil circuit;

✔Precision instruments: air bearings, metrological ring gauges;

✔Home appliance manufacturing: air conditioning compressor bearing hole;

✔Various hole types: through hole, blind hole (hole with no bottom), hole with key-way, stepped hole.

Compared with traditional honing, the advantages of reaming can be summarized as “three highs”:

While traditional honing requires repeated grinding, reaming can be completed in a single stroke, making the process 3-5 times faster! This makes it suitable for high-volume production and significantly reduces processing costs.

✔ High precision

Cylindrical error is controlled within 1μm, roughness Ra is less than 0.1μm, and the accuracy is comparable to manual grinding.

✔High adaptability

Conclusion:

The birth of the honing process is not only an advancement in processing technology, but also a microcosm of China’s manufacturing moving towards high-end precision. In the future, with the rapid development of industries such as new energy vehicles, semiconductor equipment, and aerospace, the application of the honing process will become more extensive.

What are your thoughts on honing? Feel free to leave a comment and share your thoughts! (19900928906)