10

Oct

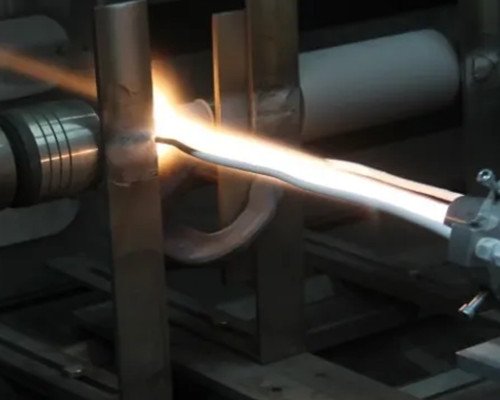

HVOF (High-Velocity Oxygen-Fuel) is a supersonic flame spraying technology developed by James A. Browning Company in the United States in 1982. This technology uses high-pressure oxygen to assist combustion through specially designed combustion chambers and nozzles to produce extremely high-speed combustion flames.

High-speed combustion flame flow: The speed of the combustion flame is several times the speed of sound, so that the spray material particles can be heated to a molten or semi-molten state and accelerated to a speed of up to 300-500m/s.

High-quality coating: HVOF technology can produce high-strength, dense, high-quality coatings, and its performance is better than thermal spraying technologies such as plasma spraying and arc spraying.

Applications of HVOF spraying:Due to its superior performance, supersonic flame spray coatings have been widely used in aerospace (engine compressor blades, bearing sleeves, etc. are basically standardized), steel metallurgy, petrochemicals, papermaking and biomedicine.

Specifically, they are: various molds such as glassware; repair of parts such as centrifugal pumps, axial flow pumps, steam boilers and mixer shaft seals; wear-resistant coatings for wear parts such as fan impellers and ball mills; high-temperature protective coatings for gas turbine blades, flame tubes, and transition sections; door cores, door rods, ball valve cores, and valve accessories; agriculture, machinery and textile industries; anti-cavitation and wear-resistant coatings for turbine blades; various process rollers in steel mills; corrugated rollers; hydraulic plungers, etc.; extruder screws, screw drills, etc.

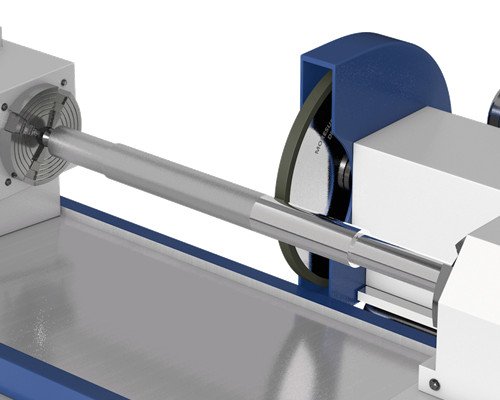

Common coating materials include metal coatings such as cemented carbide, nickel-chromium alloy, zirconium oxide, silicon carbide, and ceramic or polymer coatings. The material after spraying is relatively rough. Although it is only a thin layer, it has high hardness, high brittleness, and small processing allowance. Grinding is required to achieve a certain degree of accuracy and finish.

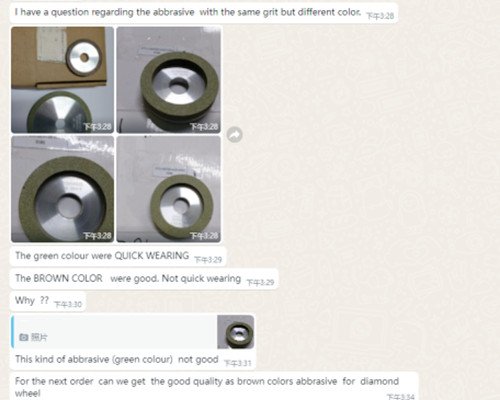

Recently,Moresuperhard received a customer’s feedback about different bond diamond grinding wheel for HOVF tungsten carbide coating roller.

He believed that the grinding effect of resin diamond grinding wheel is better than that of vitrified diamond grinding wheel.But in theory, the grinding effect of vitrified diamond grinding wheel is not worse than that of resin diamond grinding wheel. Let’s take a look at the characteristics of these two bonded grinding wheels.

Resin bond diamond grinding wheel

Resin bonded diamond grinding wheels have good self-sharpening properties. For example, they can quickly remove excess and produce good finish when used to process WC-CO coatings, which can meet the grinding requirements of most thermal spray coating customers.

Vitrified bond diamond grinding wheel

Vitrified bond diamond grinding wheel has good pore structure, high bonding strength and stable grinding performance, which is very suitable for grinding high hardness coatings, such as ceramic coatings. Its grinding efficiency and life are better than resin grinding wheels, but it has higher requirements for equipment, and it is difficult for general equipment to give full play to its high speed and high grinding performance characteristics.

Therefore,We generally recommend customers to use resin diamond grinding wheels to grind thermal sprayed workpieces, which generally achieve good grinding results. However, if customers have higher grinding requirements and equipment conditions permit, we recommend using vitrified diamond grinding wheels.

MORESUPERHARD has more than ten years of experience in thermal spraying industry. It has mature special formulas for coatings of different materials and can provide complete solutions for integrated grinding and polishing. Its stable and reliable ceramic/resin bonds and diamond/CBN grinding wheels are highly recognized by customers in the iron and steel metallurgy, aerospace, textile, transportation, petroleum and energy industries at home and abroad.