03

Jan

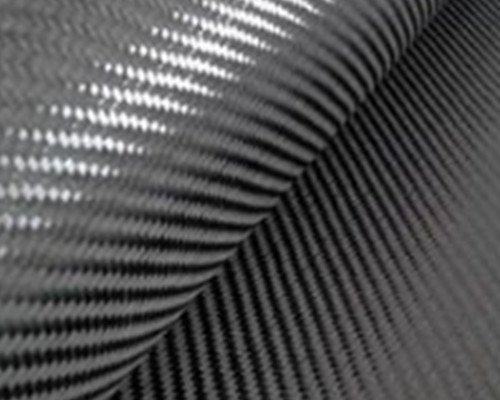

CFRP(carbon fibre reinforced plastics) is a new material formed by curing carbon fiber and resin. Carbon fiber is an anisotropic material and resin is an isotropic material. In composite materials, carbon fibers are distributed orthogonally in the resin and are laid and laminated in different laying directions. Designers can perform unidirectional multi-layer arrangement or multi-directional laminated arrangement according to the usage requirements.

CFRP has the advantages of high specific strength, low density, light weight, stable structural dimensions, and high and low temperature resistance. It has become a key material for the development of my country’s aerospace, new energy, vehicle manufacturing, rail transportation and other fields.

In the process of applying CFRP as the main part in actual design, due to the high requirements for part accuracy and assembly, it is generally necessary to perform post-processing on CFRP. Currently, CFRP cutting and drilling processes mainly include mechanical processing and special processing.

Mechanical processing mainly includes cutting, drilling and milling. The commonly tools is carbide cutting tools. Cutting processing methods including water jet cutting, ultrasonic vibration-assisted processing, laser processing, etc.

Diamond cutting blades are suitable for cutting CFRP composite materials because diamonds are extremely hard and can effectively cut carbon fiber and resin matrix. They also have excellent wear resistance and thermal conductivity, which can reduce tool wear and cutting heat accumulation, and avoid material delamination and burr problems. In addition, diamond cutting blades have low cutting force and low vibration, and can provide efficient and clean cutting results, and are widely used in high-precision processing of CFRP.

MORESUPERHARD, as a professional diamond cutting blade manufacturer, presents you with the ideal choice for cutting carbon fiber composite materials! Our cutting blades use carefully adapted binders. Resin-bonded diamond cutting blades have their own elasticity and excellent self-sharpening properties. They gently protect carbon fibers during cutting, effectively avoiding delamination and tearing problems, making the cutting surface flat and smooth, and easily meeting the needs of high-precision, high-quality fine cutting; metal-bonded diamond cutting blades stand out with their super wear resistance and stability. Even in the face of high-intensity, long-term batch cutting, or thick profile processing, they can be as stable as Mount Tai, with accurate dimensions. Electroplated bonded diamond cutting blades have high cutting sharpness and smooth chip removal, and are suitable for rapid processing of complex structures and thin-walled parts.

Choose Moresuperhard diamond cutting blades to start a new experience of efficient and high-quality cutting of carbon fiber composite materials.