28

Feb

What is sapphire?

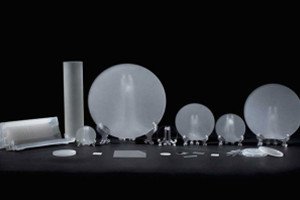

Sapphire consists of Al2O3 and has a Mohs hardness of 9, which is second only to superhard materials in hardness. Due to its superior light transmittance and wear resistance, it is mostly used in the substrate of LED light-emitting components, optical windows, and watch cases of high-end watches and cell phone cameras, etc.

Material properties of sapphire

Sapphire is hard and brittle and expensive. The processing process usually requires high precision, fast processing efficiency, low material loss and a clean working environment. Diamond is the hardest and most wear-resistant material in nature, so diamond tools are the best choice for processing sapphire materials.

Application of diamond grinding wheel in sapphire processing

Diamond grinding wheels are most widely used in the processing of hard and brittle sapphire materials. Different types of diamond grinding wheels are used from the processing of crystal ingots to rough machining of wafers and then to finishing. The picture shows four representative grinding wheels, namely ingot spheronizing grinding wheel (picture a), surface grinding wheel (picture b), thinning grinding wheel (picture c) and polishing grinding wheel (picture d), etc. The diamond particle size ranges from 100# to 8000 # are all involved, and the carcass materials include metal bonding agents, resin bonding agents and ceramic bonding agents.

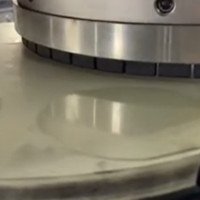

Application of ceramic diamond double-end grinding disc in sapphire wafer grinding

The sapphire window is roughly ground using a ceramic diamond grinding disc (picture below – left). Compared with the cast iron disc processing method, it has the advantages of high processing efficiency, high precision, good grinding quality, and long service life. In addition, products such as back-thinning grinding wheels and diamond grinding fluids (picture below – right) are also widely used and have great market value.

Sapphire grinding problems and solutions

Sapphire is characterized by extremely high hardness but extremely low impact strength. Sapphire substrates are susceptible to pressure and are therefore prone to damage. Due to this inherent characteristic, the wafer cannot be cut into small pieces using a diamond grinding wheel, but it can be processed using a scribing method. To produce a wafer thickness suitable for scribing, backside grinding is necessary, followed by grinding and polishing. In addition, the final thickness of the wafer is about 80um, which is ultra-thin, so it is also very important to prevent it from cracking. In short, when high-hardness grinding tools and workpieces work against each other, it is easy to cause greater surface damage. The grinding force of the grinding wheel decreases, resulting in an increase in the grinding force, which will eventually lead to wafer damage! The appropriate bonding strength of the grinding tool (grinding wheel) can better complete the grinding operation. Only when the force is greater than the bonding strength, the abrasive on the grinding tool (grinding wheel) will fall off in time, exposing a new cutting edge. The grinding tool (grinding wheel) Only then will good grinding force be maintained. The self-sharpening property of the abrasive tool (grinding wheel) is a key factor in grinding hard and brittle materials