26

Feb

Single crystal tool SCD processing jewelry ensures that the jewelry surface is shiny, smooth, free of lines and fog. At the same time, the average life expectancy has also been greatly improved. In the jewelry industry, the carving knife can engrave font patterns on the surface of platinum, gold, silver, K gold and other jewelry. With the increasingly updated processing development of the jewelry industry, more and more companies have introduced CNC equipment, and CNC processing of gold, K gold, platinum, etc. has become a trend. At the same time, stricter requirements are put forward for CNC diamond tools. For different precious metals, the design of different front and rear angle parameters plays a crucial role in tool life and the smoothness of the precious metal surface.

The gold and silver jewelry we usually wear are very beautiful, enhance the temperament, and have many engravings on the surface, so how are these exquisite jewelry processed?

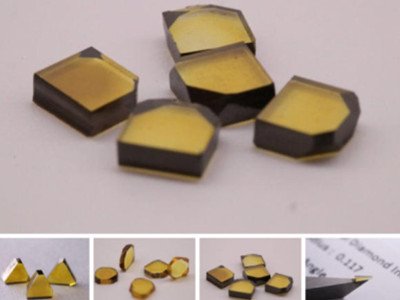

This requires machining with single crystal diamond tools. There are two kinds of single crystal diamond tools: natural and artificial. Natural single crystal diamond is small in quantity and expensive. It is mainly used for glasses, optical lenses, digital electronic optical accessories, automotive optical systems, special flying glasses for aerospace, and ultra-precision of some non-ferrous metals. cut. Synthetic single crystal diamond has the same structure as natural single crystal diamond, has the same performance and relatively low cost, and has a wide range of industrial applications and commercial prospects. The jewelry industry is also a major application industry.

Synthetic diamond is used for processing gold and silver jewelry or single crystal tools used in the jewelry industry. One of our UK customers recently purchased three different sizes of MCD tools from us to process gold jewellery. 3mm.1mm and 0.5mm.

MCD mono crystal diamond tool features

1. The welding strength is high, and the lengthened blade can be made for special processing occasions;

2. Advanced grinding technology can obtain sharp edges;

3. Some C atoms in the MCD single crystal are replaced by N atoms. Single crystal diamond has increased hardness and long tool life.

Precautions for the use of single crystal diamond tools

In order to improve the service life of the tool and avoid unnecessary problems, please pay attention to the following points when using it:

1. Do not use fingers or other objects to directly touch the diamond tip, only the workpiece;

2. Due to the hard and brittle characteristics of diamond tools, the feed rate should be from small to large during the test, and the feed rate should be from slow to fast, and the cutting amount should not exceed 0.05mm. Higher cutting speed can reduce the cutting force, while low-speed cutting will increase the cutting force, thereby accelerating the tool breakage failure. Therefore, the cutting speed should not be too low when using diamond tools.

3. During the test and turning process, please note that the tool cannot turn ferrous metals (iron metals), but can contact non-ferrous metals (gold, silver, copper, aluminum, etc.) and plastics. When ferrous metal is encountered in the turning process, the tool is very likely to be chipped, broken or even directly scrapped.

4. In the process of use, if wear occurs, it can be detected by microscope. If it is within the scope of repairable grinding, it can be repeatedly repaired and reused to save costs. If it exceeds the range of measurable wear, the tool needs to be replaced.

Application of single crystal SCD diamond tools/ mono crystal MCD diamond tool

– Natural single crystal diamond cutting tools are suitable for finishing copper, aluminum and their alloy materials, and are widely used in jewelry, clocks, instrument manufacturing, LED products, acrylic products, aluminum products, aerospace, automobiles, etc. Cameras, high-gloss parts of mobile phone parts, precious metals, various hardware high-gloss shells, watch hubs, surface calendar windows, pens, fishing gear, contact lenses, etc. It has the characteristics of low loss, long life, easy to use, etc. and can ensure extremely high machining accuracy and mirror finish.

– Single crystal diamond tools play an important role in the field of machining and are widely used in the processing of ultra-precision mirror parts such as mirrors, navigation gyroscopes for missiles and rockets, computer hard disk substrates, and accelerator electron guns. Single crystal diamond knives can also be used to manufacture ophthalmology, brain surgery scalpels, ultra-thin biological slice knives and other medical knives. In addition, the application of single crystal diamond tools in the processing of civilian products is also increasingly widespread, from the processing of watch parts, aluminum pistons, jewelry, etc. to the processing of pens, high-gloss signs and non-ferrous metal mirror decorative parts, its application has entered the machining process. various fields.

The tip materials of single crystal diamond tools are: natural diamond, single crystal, CVD

Natural diamond HPHT monocrystal diamond CVD single crystal diamond

Introduction of single crystal diamond, MCD diamond plates

Diamond is a crystal of a single carbon atom, and its crystal structure belongs to the equiaxed face-centered cubic system with the highest atomic density. The bonding bonds between carbon atoms in diamond crystals are sp3 hybrid covalent bonds, which have strong binding force, stability and directionality. The unique crystal structure of diamond makes it have the highest hardness, rigidity, refractive index and thermal conductivity in nature, as well as extremely high wear resistance, corrosion resistance and chemical stability.

The excellent characteristics of single crystal diamond can meet most of the requirements of precision and ultra-precision cutting tool materials, and it is an ideal precision cutting tool material. The uniform crystal structure of diamond without internal grain boundaries enables the cutting edge of the tool to theoretically achieve atomic level straightness and sharpness. It has strong thinning ability, high precision and low cutting force during cutting; its high hardness and good wear resistance High thermal conductivity, corrosion resistance and chemical stability can ensure that the tool has a long life, so that it can carry out continuous cutting for a long time, and can reduce the impact of tool wear on the accuracy of parts; its high thermal conductivity can reduce cutting temperature and parts Thermal deformation.

Single crystal diamond material selection

Due to the anisotropy of single crystal diamond, the properties of diamonds vary greatly in different crystal planes and directions. Correct material selection and orientation can not only simplify the processing process and reduce the manufacturing cost, but also improve the quality and service life of the cutting edge. Give full play to the excellent performance of diamond tools.

According to the impurities contained in the diamond crystal, it can be divided into four types: type Ia, type Ib, type IIa and type IIb. Generally, the particle size (weight), shape, completeness, transparency, cracks, number of inclusions, color and uniformity of diamond crystals are used as the basis for evaluating the quality of diamonds. The quality requirements of diamond for cutting tools are: complete crystal, shape is dodecahedron, arc octahedron or transition crystal, crystal diameter is generally not less than 4mm, color is colorless, light green, yellow-brown, etc., no cracks are allowed , the crystal surface is allowed to have inclusions and pits no larger than 0.5mm, and the weight is 0.7-3 carats. For ultra-precision machining tools such as ophthalmology, brain surgery scalpels, and laser mirrors that require extremely high precision, the materials should be selected from the I-grade or even gem-grade rough stones of the drawing die, and finally selected with a polarizing microscope or a more precise instrument with the smallest internal stress. of diamonds as tool blanks.

Synthetic single crystal diamond belongs to type Ib, because nitrogen atoms in its lattice uniformly replace carbon atoms, reducing the possibility of nitrogen atoms gathering at the cutting edge to form tiny chipping, and due to uniform lattice distortion, the hardness is slightly higher than that of natural ones. Single crystal diamond. In addition, due to the addition of an optimized process for removing internal stress, the cutting performance is more stable, reliable and less discrete. The direction of the crystal axis has been accurately determined when leaving the factory, so it is more suitable for the production of cutting tools. The disadvantage is that the Ib-type artificial single crystal is more brittle, and it is more difficult to process than the natural single crystal, and a fine sharpening method is required to obtain a high-quality cutting edge.