28

Aug

In the field of precision machining, the grinding quality of carbide tools directly impacts tool life and machining accuracy. However, many companies often encounter problems such as tool chipping and excessive surface roughness in actual production, which not only reduces product qualification rates but also increases production costs. Today, we will explore how to address these challenges through optimizing resin-bonded diamond grinding wheels, using a real-world case study.

一、Customer pain point: Dual challenges of chipping and surface roughness

A customer encountered two key problems when grinding carbide tools:

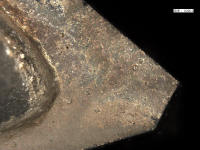

✔Chipping problem: When using grinding wheels from other manufacturers, if the grinding wheels are not dressed for a long time, the edge of the tool is prone to chipping, which seriously affects the quality of the tool;

✔High surface roughness: Even if the chipping problem is alleviated, the surface of the tool after grinding still appears obviously uneven under a 400x magnifying glass, making it difficult to meet high-precision requirements.

After analysis, we found that the occurrence of chipping may be related to the coarse abrasive grain size of the grinding wheel or the blockage of pores, while the surface roughness is closely related to the balance of the abrasive selection, porosity and grinding efficiency of the grinding wheel.

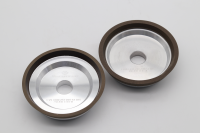

二、Solution: Optimized design of resin diamond grinding wheel

In response to customer needs, we recommend the use of resin diamond grinding wheels and have made the following optimizations:

✔Using fine-grained abrasives: Using W10-grain diamond abrasives to reduce the impact force during grinding, thereby reducing the risk of chipping;

✔Adding pore-forming agent: By increasing the porosity of the grinding wheel, it can avoid clogging by grinding chips, maintain the sharpness of the grinding wheel, and extend the dressing cycle;

✔Balancing grinding efficiency and surface quality: Under the premise of ensuring surface roughness, avoid excessive pursuit of fine grain size that leads to a decrease in grinding efficiency.

In actual application, customers reported that the chipping problem was significantly reduced, but the surface roughness still needs to be further improved. This shows that relying solely on fine-grained abrasives is not a panacea, and comprehensive optimization of the grinding wheel formula and process is also needed.

三、Industry enlightenment: the “golden balance point” of grinding wheel performance

This case reveals two core contradictions in carbide tool grinding:

✔The contradiction between particle size and efficiency: the finer the particle size, the better the surface quality, but the grinding efficiency may be greatly reduced.

✔The contradiction between porosity and durability: Although excessive porosity can reduce clogging, it may affect the strength of the grinding wheel.

四、Conclusion: Technology iteration driven by customer needs

There is no “one-size-fits-all” solution to the grinding problem of carbide tools, but it requires dynamic adjustment according to the processing scenario. As a grinding wheel manufacturer, we are always guided by customer needs and continue to explore dimensions such as particle size, porosity, and binder, striving to find the optimal balance between surface quality and grinding efficiency.

In the future, we will continue to work with industry partners to jointly promote the advancement of precision grinding technology and empower the high-quality development of the manufacturing industry!

What other problems have you encountered in carbide tool grinding? Welcome to leave a message to discuss.