19

Sep

The polishing technology will determine the imaging and lens quality for some parts processing. In the field of precision optics, there are high requirements for surface accuracy and smoothness, and it achieves nanometer level standards, surpassing normal glass processing.

Mechanical polishing: Suitable for large components, low cost, but slow.

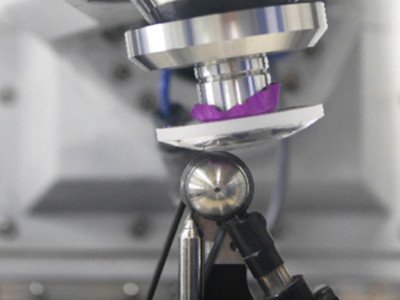

Magnetorheological polishing (MRF): Providing nanometer-level precision, capable of correcting complex curved surfaces, widely used in precision optical manufacturing.

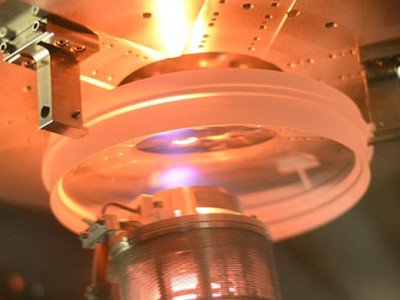

Ion beam polishing (IBP): Providing atomic-level precision, suitable for extremely high-end optical applications, such as astronomical telescopes and EUV lithography equipment.

High-performance polishing powder is key to improving efficiency and surface quality:

Cerium Oxide (CeO₂): High cutting efficiency, a mainstream choice, suitable for most optical glasses.

Zirconium Oxide (ZrO₂): Higher hardness, suitable for soft glass such as FCD/FK series.

Full Particle Size Coverage: Large particle size powder (1–5μm) for rough polishing, submicron powder (0.1–1μm) for fine polishing, meeting the needs of different stages.

Excellent Performance: Stable suspension, low sedimentation, corrosion resistance, and easy cleaning ensure smooth subsequent coating processes.

Zirconium oxide polishing liquid

Nano-sized particles, with strong cutting force

Surface roughness can be as low as 1nm

Adding anti-corrosion additives effectively solves the “white spot” problem of fluoride glass

Applications: Camera lenses, laser optical components, AR/VR optical lenses

Cerium oxide polishing liquid (Precision type)

Uniform particle size (0.1 – 1 μm), efficiency increased by more than 30%

Compatible with magnetic flow and ion beam polishing processes

Neutral formula, suitable for fine polishing before multi-layer coating

Applications: Photolithography lenses, astronomical telescope mirrors, precision filters

Cerium oxide polishing powder (various models)

From coarse polishing at 5μm to ultra-fine polishing at 0.05μm

Supports customized requirements for different glass materials and process.

Camera lenses ,Laser optical components,AR/VR optical lenses,Lithography lenses, Astronomical telescope mirrors,Precision filters