29

Aug

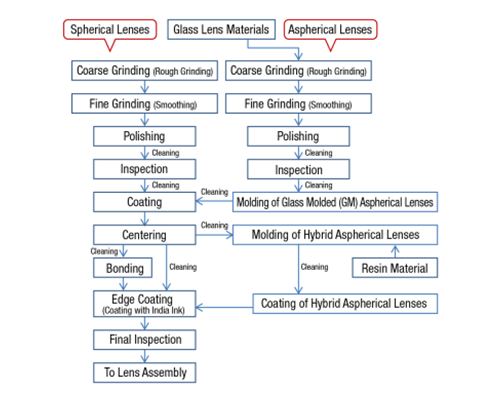

The finished surface of an optical glass lens is smooth and transparent, but it does not start out that way. In the cold processing of optical lenses, the transformation from raw glass material (commonly referred to in the industry as “blank material”) to an optical-grade mirror surface requires three core processes: coarse grinding, fine grinding, and lapping/polishing. From their names, it is clear that the machining precision of these processes increases step by step, and together they form the key stages of lens shaping.

As continuous and closely connected processes, coarse grinding, fine grinding, and lapping/polishing differ significantly in machining purpose, material removal rate, surface quality, choice of tools/abrasives, and precision requirements:

Coarse Grinding

The core objective is “rapid forming”, removing a large amount of material through high-efficiency machining to roughly shape the blank material to near-design dimensions. After this step, the lens surface remains highly rough and cannot meet optical requirements.

Fine Grinding

Focused on “precise shaping”, this step removes a small amount of material to correct shape deviations and eliminate surface defects left by coarse grinding (such as scratches and unevenness). It prepares the lens for polishing. After fine grinding, the surface appears matte or frosted; while shape accuracy improves significantly, the lens is still not smooth enough.

Lapping/Polishing

The key task here is “fine polishing”. Material removal at this stage is minimal, often negligible. The ultimate goal is to bring the surface to optical-grade smoothness, creating a bright, flat mirror surface that meets the strict surface quality requirements of optical performance.

An Illustrative Analogy

To better understand their functional differences, these processes can be compared to woodworking:

Coarse grinding is like cutting wood with an axe—emphasis on speed and rough shaping (like producing a furniture blank), with no concern for surface finish.

Fine grinding is like refining wood with coarse and fine files—gradually correcting the shape to near-final dimensions, while leaving minor surface marks.

Lapping/polishing is like sanding wood with progressively finer sandpapers, ultimately achieving a smooth and delicate surface ready for use or further finishing (such as painting).

Increasing Precision and Fineness

From abrasive grit size and tool selection to surface roughness and dimensional accuracy, the trend follows: Coarse < Fine < Polishing. The further the process advances, the higher the level of refinement.

Decreasing Material Removal Rate

Material removal rate decreases progressively: fastest at coarse grinding, lower at fine grinding, and negligible at polishing, which focuses purely on surface optimization.

Evolution of Machining Purpose

Coarse grinding emphasizes efficiency and shaping, quickly forming the rough outline.

Fine grinding emphasizes accuracy and correction, improving dimensional precision and eliminating surface flaws.

Polishing emphasizes surface quality, producing an optical-grade mirror finish.

Surface State Transition

After coarse grinding: rough, opaque surface.

After fine grinding: matte/frosted surface, geometrically accurate but lacking luster.

After polishing: smooth, transparent mirror surface.

These three stages are interdependent and jointly determine the final optical performance of the lens (such as diopter accuracy, aberration control, and transmittance) as well as its appearance quality. Any deviation at one stage—excessive shape errors in coarse grinding, surface defects left from fine grinding, or insufficient accuracy in polishing—will directly compromise the final product, rendering the lens unfit for optical applications.