06

Aug

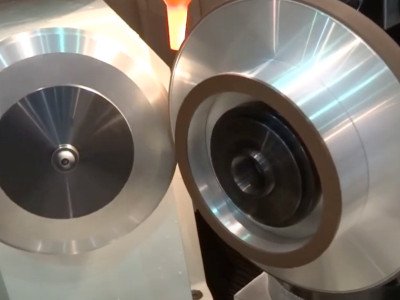

At Moresuperhard, we are committed to providing tailored solutions that address our customers’ unique grinding challenges. One such case involved a customer in Lithuania, specializing in the regrinding of hard alloy tobacco cutting blades. The customer faced several issues that hindered their production efficiency and quality, particularly regarding blade edge wear, low grinding efficiency, and tool breakage. Here’s how we helped optimize their process.

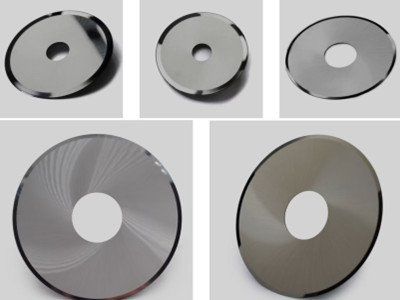

Rough Grinding: The customer used a 200×31.75mm 1A1 resin-bonded diamond wheel with a grain size of D46. The material removal was set at 0.5mm per pass, removing a total of 1mm around the circumference.

Finishing: A 250×31.75mm 1A1 resin-bonded diamond wheel with a grain size of 2000# was used. It took around 3-4 minutes to grind each side of the blade, with a total finishing time of about 10 minutes for both sides.

By optimizing grinding wheel thickness, grain size, infeed, and spindle speed, our customer in Lithuania was able to enhance the efficiency of their hard alloy tobacco cutting blade regrinding process. These adjustments not only resolved existing issues such as tool breakage and chipping but also improved overall production efficiency. With these recommendations, the customer is well-equipped to meet future production demands with higher precision and faster turnaround times.

At Moresuperhard, we continually strive to provide innovative solutions to improve the grinding processes of our customers. If you are facing similar challenges, don’t hesitate to contact us for expert advice and tailored solutions.