27

Aug

Sapphire is one of the hardest and most wear-resistant materials in industrial applications. It is widely used in optical components, electronic substrates, semiconductors, and high-end watch crystals due to its exceptional hardness, high transparency, and durability. However, before sapphire can be transformed into a finished product, it must undergo a series of precision processes—cutting, grinding, and polishing. Among these, polishing is a key procedure that directly determines the surface quality, roughness, and flatness of the final workpiece.

A customer engaged in sapphire and steel component processing needed to improve the surface quality of sapphire parts. Their requirement was for large-diameter polyurethane polishing pads that could provide:

High surface flatness and smoothness

Stable wear resistance under long polishing cycles

Customized hardness to adapt to different processing conditions

The specified polishing pads were:

Size: D762 × T1.27mm

Type: MSH-57 and MSH-87

Workpieces: Sapphire and Steel

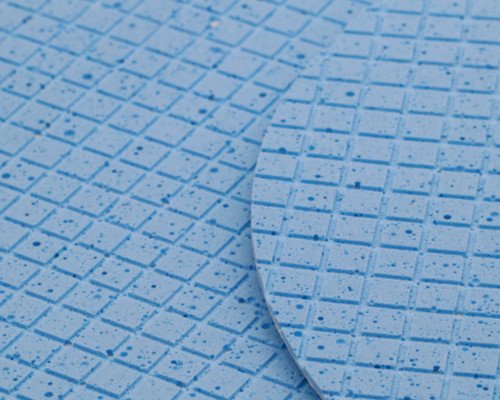

To meet the challenges of sapphire’s extreme hardness, MORESUPERHARD supplied polyurethane CMP polishing pads. These pads combine both elasticity and durability, making them ideal for sapphire’s demanding polishing requirements.

Custom Hardness: Tailored pad hardness ensures optimal polishing performance for sapphire and steel.

CMP Technology: By working with polishing liquid, the pads remove microscopic surface unevenness through chemical-mechanical interactions, achieving ultra-high surface precision.

Stable Performance: The pads maintain consistent polishing quality even under continuous abrasive action.

Improved Efficiency: Reduced polishing cycle time while ensuring excellent surface quality.

The customer reported that after adopting MORESUPERHARD polyurethane polishing pads, the sapphire workpieces achieved:

Superior surface roughness meeting industry standards

High smoothness and flatness, suitable for optical applications

Longer pad life compared to conventional polishing materials

Sapphire polishing demands not only high precision but also highly durable polishing consumables. MORESUPERHARD polyurethane polishing pads provide a reliable solution, combining elasticity, wear resistance, and customizable hardness to help customers achieve exceptional surface quality in sapphire processing.

Whether for sapphire, steel, or other hard materials, MORESUPERHARD continues to deliver tailored polishing solutions to meet the ever-evolving needs of advanced materials manufacturing.