07

Jan

Grinding: The first step in edge treatment, using hard abrasive tools such as diamond wheels to remove the rough parts of the cut glass edge, obtaining precise dimensions and a basic shape. The treated edge has a matte or frosted glass effect, with microscopic cracks and rough texture on the surface.

Chamfering/Beveling: This process transforms sharp right-angled edges into bevels or rounded corners (R-angle/C-angle). The core purpose is to improve operational safety, prevent scratches, reduce stress concentration, and lower the risk of chipping or breakage.

Polishing: As the final step in finishing, polishing significantly reduces the roughness of the edge surface through fine grinding or chemical action, achieving a smooth, bright, or even mirror-like effect. This step is crucial for ensuring optical performance and mechanical strength.

Improving Mechanical Strength and Durability

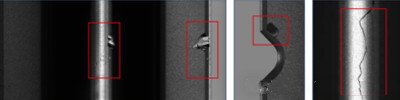

After cutting and grinding, glass edges often retain microscopic cracks that can easily propagate under external force, leading to breakage. Polishing removes the damaged layer containing cracks layer by layer and blunts the edge contour, resulting in a more even stress distribution and significantly enhancing resistance to fracture and thermal shock.

Ensuring Cleanliness and Subsequent Processing Quality

Edges that have only undergone grinding and chamfering are still relatively rough and prone to retaining debris. This debris may detach during subsequent handling, cleaning, or heat treatment, contaminating the surface or affecting assembly accuracy. The smooth, dense surface layer created by polishing inhibits debris generation at its source, ensuring glass cleanliness and processing stability.

Meeting Optical and Functional Adaptation Requirements

Optical glass (such as lenses and windows) requires polished edges to reduce light scattering and absorption, ensuring a clear light path;

consumer electronics cover glass enhances visual quality through polishing;

precision components (such as microfluidic chips and vacuum glass components) rely on smooth edges to achieve functions such as leak-free sealing and low-loss coupling.

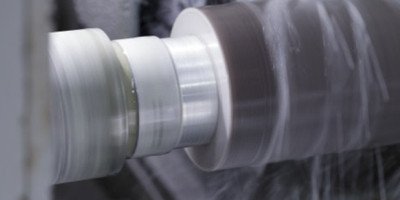

Main tools for mechanical polishing: Polishing wheel + polishing compound

Polishing wheel: Soft resin-bonded fine grinding wheels, felt wheels, or wool wheels are selected. Their core function is to evenly bear and apply the polishing compound without strong cutting force.

Polishing compound: Nano-grade cerium oxide is commonly used. It reduces edge roughness through chemical-mechanical action, balancing polishing efficiency and surface quality.

Brush Polishing

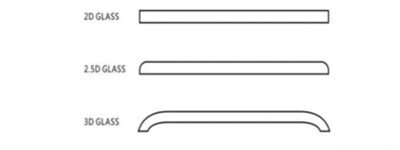

In the mass production of mobile phone cover glass (especially 2.5D and 3D curved glass), cerium oxide polishing powder or polishing liquid is injected onto the working surface (polishing carpet, wool felt wheel or brush) of a high-speed glass polishing machine. The glass is then simultaneously brushed and polished at the edges and surface through high-speed rotation and friction, making its surface bright.

Glass stacked edge polishing

This is commonly seen in round glass, where the edges of the glass wafer are polished. There are also two types:

Horizontal stacked edge polishing

Glass vertical stacking edge polishing

The traditional edge polishing methods described above have three inherent limitations:Uncontrolled edge morphology;uneven polishing depth;limited roughness improvement.

Obtain controllable edge morphology

Controllable surface finish

Therefore, edge band polishing might be a more suitable method.

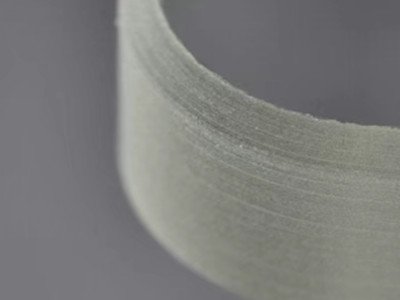

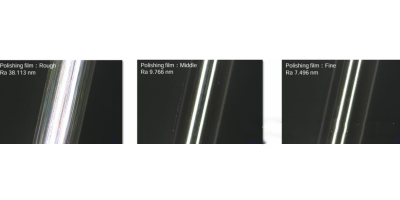

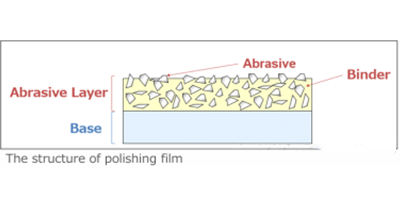

Tape edge polishing is a mechanical polishing method that uses a polishing tape as its core tool. As an alternative to edge grinding machines, it is primarily used for edge processing of precision components such as semiconductor wafers. It allows for flexible adjustment of edge roughness and chamfer shape, adapting to the polishing needs of various materials and layered structures. Key features include a unique polishing unit that uses a soft pad to conform the polishing tape to the wafer edge shape with relatively gentle pressure; for wafer notches, the tape (3mm wide) needs to be stretched to fit the notch contour; changing the polishing tape adjusts the roughness and shape, enabling edge trimming (removing layered materials to create bevels instead of 90-degree angles); the polishing tape contains specific abrasives, with different grit sizes (600-20000 grit) corresponding to different precision levels.

The process features a unique polishing unit that uses a soft pad to conform the polishing belt to the wafer edge shape with gentle pressure. For wafer notches, the belt (3mm wide) needs to be tightened to fit the notch contour. The roughness and shape can be adjusted by changing the polishing belt, enabling edge trimming (removing layered material to form a bevel instead of a 90-degree angle). The polishing belt contains specific abrasives, with different grit numbers (600-20000 grit) corresponding to different precision.

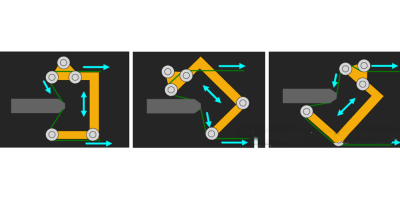

Polishing method diagram

For irregularly shaped glass, especially at notched locations, the positions of the working stage and polishing head can be flexibly adjusted.

Compared to glass stacking edge polishing and mobile phone cover glass sweeping polishing, the core advantages of belt edge polishing when applied to glass can be summarized in three points:

Enhanced precision and detail adaptability: It can conform to irregular glass edges (such as notches and special contours), precisely controlling edge roughness by adjusting the grit of the polishing belt. This avoids the problems of missed notches in stacking polishing and insufficient precision in sweeping polishing, making it suitable for scenarios with high requirements for edge detail, such as optical glass and precision glass wafers.

Lower glass damage rate: The soft pressure bonding method of soft pads + polishing belts significantly reduces brittle damage such as micro-cracks and edge chipping at glass edges, avoiding the breakage caused by uneven force in stacking polishing and the surface roughness damage caused by sweeping polishing.

Higher process flexibility and yield: It eliminates the need for complex anti-scratch tooling of stacking polishing and the fixed process of sweeping polishing. Changing the polishing belt allows for quick switching of precision/shape requirements, resulting in higher yield per process. It also adapts to the edge processing needs of different types of glass (optical, thin, and laminated glass).

As the industry’s pursuit of glass components shifts from “functional realization” to “ultimate performance,” edge processing has also moved from simply “polishing to a shine” to a precision era of “controlled shape and roughness.” This is not merely an improvement in process, but a crucial step in glass processing’s transition from traditional manufacturing to precision engineering.

The future of glass edge polishing will be a deep integration of materials science, precision mechanics, intelligent control, and digital modeling. Its goal is no longer just “smoothness,” but to provide impeccable boundary conditions for achieving higher performance, smaller size, longer lifespan, and more reliable operation in the final product.