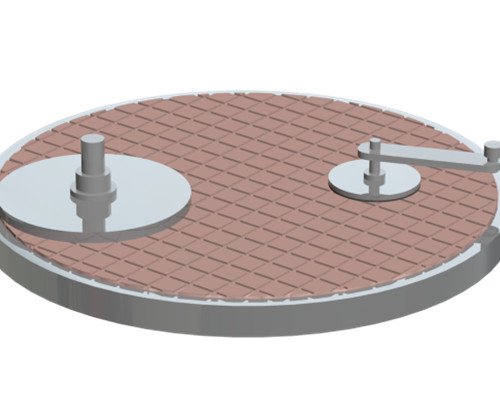

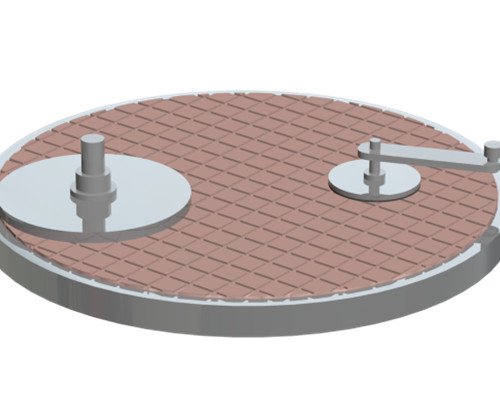

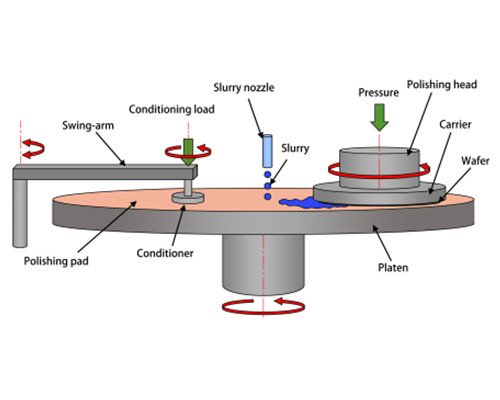

CMP (Chemical Mechanical Polishing) dresser is a special tool used to dress the grinding disc or polishing pad during the process of Chemical Mechanical Polishing. Its main function is to perform fine dressing on the surface of the polishing pad through diamond or other hard materials to restore its flatness and grinding performance, thereby ensuring the stability of the process and the polishing quality.

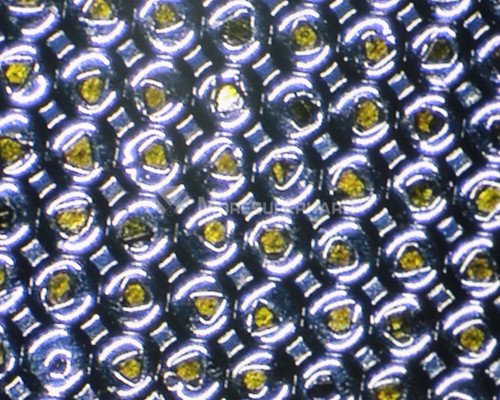

High Hardness: Diamond is the hardest known material, effectively removing wear layers and residues from polishing pads, restoring their original texture and ensuring polishing quality and efficiency while extending dresser lifespan.

Corrosion Resistance: Exceptional chemical stability prevents reactions with acidic or alkaline components in polishing fluids, ensuring durability and maintaining a clean polishing environment.

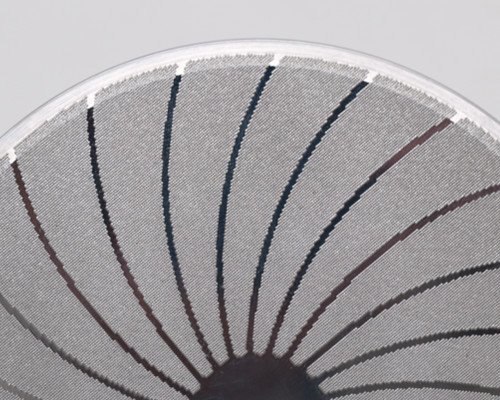

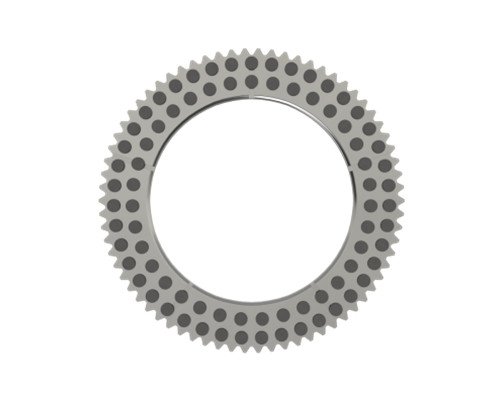

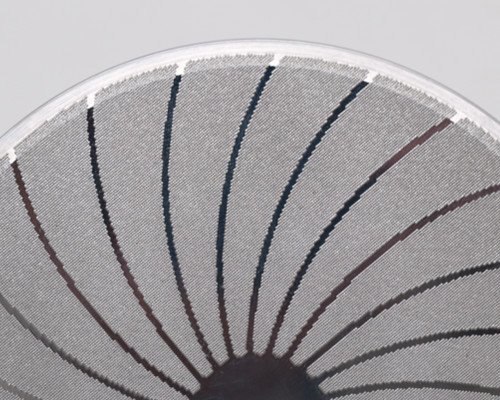

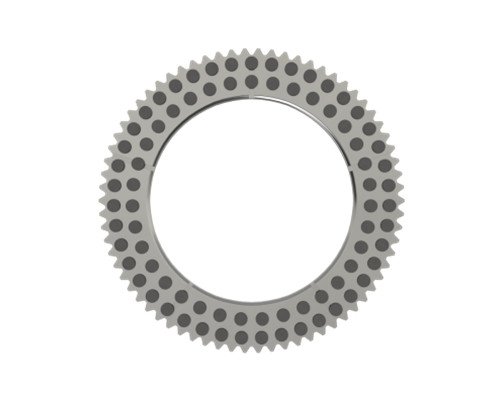

Precision Dressing: Features an orderly arrangement of diamond particles (matrix or concentric pattern), ensuring even load distribution for each particle, improving dressing precision, and reducing surface defects.

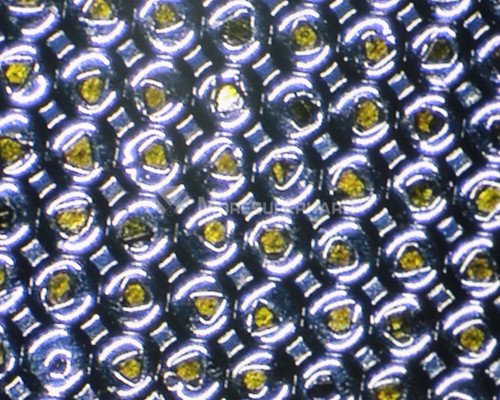

Multiple Bonding Technologies: Available in sintered, electroplated, and brazed bonding methods to meet different dressing needs.

Sintering: Long lifespan and self-sharpening properties, though with relatively lower dressing efficiency.

Electroplating (EP): High dressing efficiency, uniform diamond distribution, but particles may detach, affecting lifespan.

Brazing: High dressing efficiency, strong adhesion, and extended service life.

Semiconductor wafer manufacturing (such as silicon wafers, compound semiconductor wafers).

Precision optical component processing.

Surface treatment of flat panel display (TFT-LCD) glass substrates.

| Specification | Details |

| Diamond Grit Size | Available in multiple grit sizes, such as 5μm, 10μm, and 20μm, precisely matched to different polishing requirements, covering rough to fine polishing needs. |

| Base Material | Made of high-strength, wear-resistant special alloy material, ensuring excellent rigidity and stability. This prevents deformation during high-speed rotation and prolonged use, extending the dresser’s service life. |

| Dresser Size | Diameter range: 50mm – 200mm, customizable to fit various polishing equipment specifications; Thickness: 10mm – 30mm, adjustable based on application needs for optimal dressing performance. |

| Connection Method | Equipped with standard threaded interfaces or flange connections for quick and easy installation. It securely attaches to polishing equipment, ensuring stability and safety during high-speed operation. |

| Compatible Polishing Pad Types | Suitable for polyurethane polishing pads, non-woven polishing pads, and other common CMP pad materials. High versatility allows broad application across different polishing processes. |

Customer Need: Enhance CMP pad dressing precision and extend dresser lifespan.

Solution: Adopt an orderly-arranged brazed diamond dresser to ensure uniform dressing and minimize particle detachment.

Outcome: Dressing efficiency improved by 20%, and dresser lifespan increased by 30%.

Customer Need: Reduce defects caused by inadequate dressing during polishing.

Solution: Recommended an electroplated diamond dressing disk for high-efficiency and precise dressing.

Outcome: Polishing efficiency increased by 25%, significantly improving glass surface quality.